Evaluation of Physicochemical and Microbiological Characteristics of Different Soy sauces Sold in Phnom Penh, Cambodia

Article Information

Luka Ly1, Lay Phikhher Eav2, Monychot Tepy Chanto1,2, Pramuk Parakulsuksatid3, Reasmey Tan1,2*

1Research and Innovation Center, Institute of Technology of Cambodia, Russian Federation Blvd., P.O. Box 86, Phnom Penh, Cambodia

2Faculty of Chemical and Food Engineering, Institute of Technology of Cambodia, Russian Federation Blvd., P.O. Box 86, Phnom Penh, Cambodia

3Faculty of Agro-Industry, Kasetsart University, 50 Ngam Wong Wan Rd, Lat Yao Chatuchak, Bangkok 10900, Thailand

*Corresponding Author: Reasmey Tan, Institute of Technology of Cambodia, Russian Federation Blvd., P.O. Box 86, Phnom Penh, Cambodia.

Received: 10 October 2023; Accepted: 19 October 2023; Published: 25 January 2024

Citation: Luka Ly, Lay Phikhher Eav, Monychot Tepy Chanto, Pramuk Parakulsuksatid, Reasmey Tan. Evaluation of Physicochemical and Microbiological Characteristics of Different Soy sauces Sold in Phnom Penh, Cambodia. Journal of Food Science and Nutrition Research. 7 (2024): 14-21.

Share at FacebookAbstract

In Cambodia, there are many different types of soy sauce sold in the markets. Some of them are imported from different countries, and some are locally produced. However, the quality of soy sauces sold in the markets has not yet been evaluated. Therefore, this study aimed to evaluate the physicochemical and microbiological characteristics of different soy sauces sold in Cambodia. In this study, forty-two light soy sauces of different origins sold in local markets and supermarkets in Phnom Penh were selected for physicochemical and microbiological analyses. The quality of these 42 soy sauces was evaluated by comparing to the Cambodian Standard for soy sauce products (CS 066:2011) and China National Food Safety Standard. As a result, there were only eight soy sauce samples that had high quality as grade 1 of light soy sauce categorized by the Institute Standards of Cambodia, including one Cambodian soy sauce (C7), two Thai soy sauces (Th6 and Th12), one Singaporean soy sauce (S2), two Japanese soy sauces (J1 and J2), one Malaysian soy sauce (M) and one Taiwanese soy sauce (T). For microbiological quality, three soy sauces had the presence of halophilic yeasts, including two brands of Cambodian soy sauce (C2 and C7) and one brand of Thai soy sauce (Th5). A total viable count was detected in 50% of soy sauces, but they were under the standard limit and safe for consumers according to National Food Safety Standard of the People's Republic of China (GB 2717-2018).

Keywords

Cambodian markets; Light soy sauce; Physicochemical analysis; Microbiological analysis; Amino acid nitrogen; Total nitrogen; Salt

Cambodian markets articles; Light soy sauce articles; Physicochemical analysis articles; Microbiological analysis articles; Amino acid nitrogen articles; Total nitrogen articles; Salt articles.

Article Details

1. Introduction

Soy sauce has been a liquid condiment of Chinese origin since 2200 years ago [1] and it is widely used in Asian and some Western foods for improving the taste and flavor, as it is the primary source of natural umami taste and kokumi [2,3]. Not only the taste and flavor, but a good quality soy sauce contains many beneficial compounds that benefit human health, such as bioactive compounds, antioxidants, anticarcinogenic effects, antihypertensive, antidiabetic, reduction menopausal symptom, and antimicrobial [4-6]. In Cambodia, almost every family has a bottle of soy sauce at home [7]. Soy sauce is produced from the fermentation by using the main ingredients such as soybean and wheat inoculated with the Aspergillus oryzae or Aspergillus sojae, and then koji continues to do the fermentation in a brine solution with the combination of halophilic bacteria and yeast [8]. Soy sauce is mainly divided into 2 main styles such as Chinese style and Japanese style, for Chinese soy sauce, the ratio of wheat is lower than soybean, and the Japanese soy sauce style mainly uses the ratio of wheat and soybean equally [9]. Besides wheat and soybean, soy sauce can be produced from other gain materials too [10,11]. Soy sauce is also produced via acid hydrolyzation or enzyme hydrolysis [12], and then, the flavor and color are added to make soy sauce. Soy sauce made from acid hydrolysis does not benefit human consumption and may contain dangerous substances that negatively affect consumers [13,14]. According to the Institute Standards of Cambodia, light soy sauces are divided into grade 1 and grade 2. For grade 1, the pH of the soy sauces must be from 4.2 to 4.6, the salt content must not be over 20 g/100 mL, the soluble salt-free solid should range between 15 and 18g/100mL, the total nitrogen should not lower than 1g/100 mL, and the amino acid nitrogen is at least 0.35g /100 mL. In contrast, for grade 2, the total nitrogen and total amino acid nitrogen must be at least 0.8 g/100 mL and 0.26 g/100 mL, respectively. And halophilic yeast must not be detected in both grades. Cambodian soy sauce made by fermentation has not yet been recognized widely in Cambodia. Nowadays, the need for soy sauce is increasing, that is why many soy sauces are imported, and the soy sauce production has increased in Cambodia. There are many soy sauces sold in Cambodia, including Cambodian soy sauces and those imported from other countries, such as Vietnam, Thailand, Japan, Singapore, etc. In addition, the quality of all soy sauces, including its physicochemical and microbiological quality, has not yet been evaluated. Therefore, the current study aims to evaluate the quality of different soy sauces sold in Cambodia based on the Institute of Standards of Cambodia, and National Food Safety Standards of the People's Republic of China.

2. Materials and methods

2.1 Sample preparation

The 42 soy sauce samples were randomly purchased from the local markets and supermarkets in Phnom Penh, Cambodia. Nine samples were Cambodian soy sauces coded C1–C9, 13 samples were Thai soy sauces coded TH1–TH13, seven samples were Chinese soy sauces coded CH1–CH7, four samples were Vietnamese soy sauces coded V1–V4, two samples are Singaporean soy sauces coded S1–S2, two samples are Japanese soy sauces coded J1–J2, one sample is Malaysian soy sauce coded as M, one sample is Hong Kong soy sauce coded as H, a sample is Korean soy sauce coded as K, a sample is Taiwanese soy sauce coded as T, and the last one is French soy sauce coded as F. All the samples were stored in the dark at room temperature and closed before analysis.

2.2 pH of soy sauces

The pH meter (HANA instrument, Woonsocket) was used to measure the pH of soy sauces. The pH meter was first calibrated with pH buffers before measuring the pH of soy sauces. In each experiment, the electrode was washed well with distilled water, and soft tissue was used to dry it before calibrating or measuring the pH of soy sauces.

2.3 Salt content of soy sauces

The salt meter with model ES-421 (Atago, 2017), ranging from 0-10%, was used in this experiment to measure the soy content in the soy sauces. Before using the salt meter, the salt meter was calibrated with the salt standard, as the salt meter can only be used to analyze the salt content within the range between 0 and 10%. Still, the soy sauce could have a salt content of more than 10%; thus, the soy sauce was diluted to a range between 0 to 10%, recorded the result shown on the screen, and calculated with the dilution factor after calculating the unit of salt was considered as g/100 mL.

2.4 Soluble salt-free solid content of soy sauces

An oven (Beschickung/Loading-Modell 100-800) was used in this experiment to analyze the soluble salt-free solid content. An aluminum cup was transferred to the oven at a temperature of 105 °C for about an hour then the cup was transferred to the desiccator for about 15 min, the cup was weighed and recorded, and 2mL of soy sauce sample was pipetted into the aluminum cup. After that, the cup with the sample was transferred to the oven, heated at 105 °C for 24 hours, then transferred to the desiccator for 15 min, then weighed [15]. The soluble salt-free solid content of soy sauce was then calculated as follows:

Where A is the cup's weight, B is the cup's weight and the sample before drying, C is the cup's weight and the sample after drying, and SC is the salt content in grams per 100 mL.

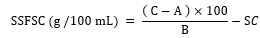

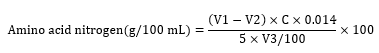

2.5 Total amino nitrogen of soy sauces

Amino acid nitrogen was analyzed using the Chinese National Standard (GB/T 5009.39-2003) method. For the analysis, 5 mL of soy sauce was pipetted into 100 mL of the volumetric flask and then filled with water until the sample reached the mark, then mixed well. In the next step, 20 mL of diluted sample were placed in a 200 mL beaker and then filled with 60 mL. After that, the mixture was titrated with 0.05 mol/L sodium hydroxide standard solution until pH 8.2. Later on, 10 mL of formaldehyde solution was added and mixed well. Then, 0.05 mol/L sodium hydroxide standard titration solution was used and continued titration to pH 9.2, and the volume of sodium hydroxide was recorded. After that, the blank sample was analyzed by taking 80 mL of distilled water and adjusting the pH to 8.2 with 0.05 mol/L sodium hydroxide solution; then added 10 mL of formaldehyde solution and titrated with 0.05 mol/L sodium hydroxide solution until the pH reached to 9.2. The volume titrated was recorded. The content of amino acid nitrogen in the sample was then calculated as follows:

Where V1 is the volume of NaOH standard titration solution after adding formaldehyde in the sample, V2 is the volume of NaOH standard titration solution after adding formaldehyde in the blank test, C is the concentration of NaOH standard titration solution, and V3 is the volume of diluted sample.

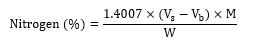

2.6 Total nitrogen of soy sauces

Total amino nitrogen was analyzed following the method described in AOAC’s official method 991.20. 15.00 g of K2SO4, 1mL of 0.05g/mL CuSO4.5H2SO4 catalyst, and 8-10 boiling chips were added to the digestion flask. Soy sauce samples were warmed to 38 °C, and 5 mL were immediately placed into the digestion flask. 25 mL H2SO4 was added and then rinsed soy sauce on the neck of the flask into the bulb. Digest and distill a blank. The flask was placed with a fume ejection system. After that, digest for 90 min. At the end of digestion, the digest should be clear and free of undigested material. Keep acid digestion at room temperature for about 25 min. After the digest has cooled to room temperature, add 300 mL of water to the flask and swirl to mix. 50 mL of 4% H3BO3 solution with indicator was transferred to a 500 mL graduated Erlenmeyer titration flask and then placed the flask that digested by adding 75 mL of 50% NaOH to the flask. All NH3 was distilled (≥200 mL of total volume), then H3BO3 receiving solution was titrated with standard 0.1000M HCl solution to the first trace of pink. For nitrogen loss, 0.12 g ammonium sulfate and 0.85 g sucrose were used per flask, then do the same experiment as above. Recoveries shall be at least 99%. For digestion efficiency, 0.16 g lysine hydrochloride or 0.18 g tryptophan with 0.67 g sucrose was used, then digested and distilled under the same conditions as above. Recoveries shall be at least 98%.

Where Vs and Vb are the volume of HCl titrant used for the test portion and the blank, respectively; M is the molarity of HCl solution, and W is the test portion weight in grams.

2.7 Reducing sugars of soy sauces

Preparation of DNS Reactive (solution A) was prepared by dissolving 1.00g of DNS in 20 mL of NaOH 2M, the solution B was prepared by dissolving 30 g of sodium and potassium tartrate tetrahydrate in 50 mL of distilled water and stirring until complete dissolution, then mix solution A onto B, heat and swirl to homogenize them complete the volume to 100 mL with distilled water with amber bottle at 4 °C to use. After creating the DNS Reactive, 0.5 mL of soy sauce sample was withdrawn and mixed with 0.5 mL of distilled water, pipette 2 mL of DNS reagent, mixed well, and then boiled for 5 minutes; after that cooling down and combined with 7 mL of water, vortexed until becomes homogenous, then transferred to the spectrophotometer (BK-D580 Spectrophotometer) within the wavelength of 540nm. DNS reagent was used as the blank solution, and D-glucose was applied as the standard solution [16]. The results were determined as g/L by a linear glucose calibration curve (R2>0.9993).

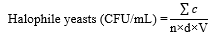

2.8 Halophile yeasts

Halophile yeasts were cultured by using Potato Dextrose Salt agar as described in Cambodian Standard (CS 066:2011). The medium was made by weighting 24 g of potato dextrose broth powder and 15 g of agar powder together in a 1000 mL bottle with 100g of sodium chloride, then stirred and autoclaved at 121 °C for 15 min, kept it until reaching 45 °C in the water bath and added 10 mL of 10% tartaric acid solution to inhibit the bacterial growth, then the medium was poured into the plate for about 25 to 30 mL and kept until cool, 0.1 mL of the soy sauce sample was pipetted to the hard agar media, then a spreader was used to spread over the agar until dry. The number of yeast colonies was calculated as shown below:

Where ∑c is the sum of counted colonies, n is the number of plates, d is the dilution factor, and V is the amount of inoculating volume.

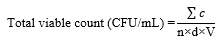

2.9 Total viable count

The total viable count was obtained according to the National Standard of the People's Republic of China (GB 4789.2-2016). One mL of soy sauce was serial diluted with buffered sodium chloride (100 to 10-2). After pouring 15-20 ml of PCA agar into Petri dishes at 45±1 °C, diluted samples were poured into Petri dishes, then doing a gentle swirl it until it was well distributed in the media, then waiting until hardened. Then, the petri dishes were placed upside down into the incubator at 36°C±1 °C for two days. The agar plates selected for counting must have colonies between 30 and 300 per dish to make the result more accurate.

Where ∑c is the sum of counted colonies, n is the number of plates, d is the dilution factor, and V is the amount of inoculating volume.

2.5 Statistical analysis

The experimental results were analyzed by using SPSS version 23 (SPSS Inc., Chicago, Illinois), triplicate experiments were conducted on each sample and the data was represented in the form of mean ± standard deviation (SD). The analysis of variance (ANOVA) with Tukey's test was performed to evaluate the significant differences in physicochemical parameters of different soy sauce samples, and a significant difference was defined as p<0.05.

3. Results and discussion

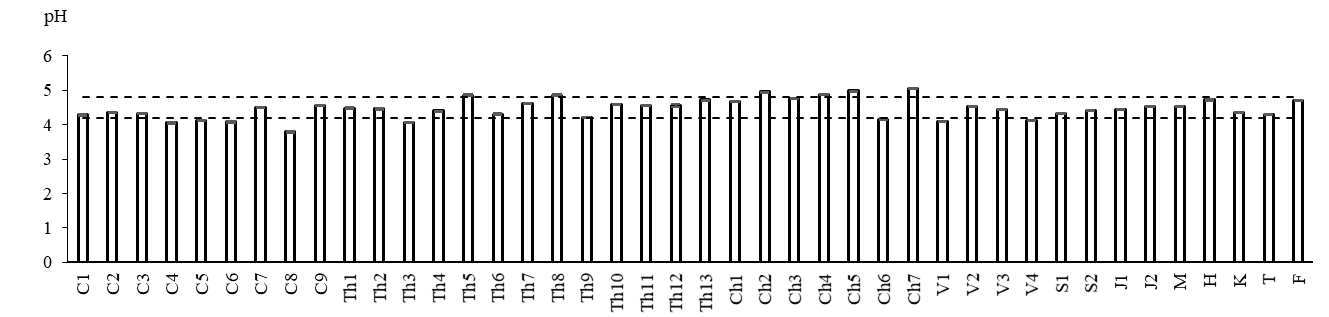

3.1 pH values of soy sauces sold in the markets

The pH is an essential part of determining the quality of soy sauce. According to the Institute of Standard of Cambodia, the pH in soy sauce should be around 4.2 to 4.6 (CS066:2011, 2012). During fermentation, lactic acid bacteria grow and decrease the pH of the soy sauce between 4 to 5 [17]. Low pH has the benefit of preserving the soy sauce, and high acid food, which has a pH below 4.6, could inhibit the growth of most bacteria spores; that is why pasteurization is enough to kill the spoilage microorganism and preserve soy sauce [18]. As shown in figure 1, the pH values of the soy sauce samples were between 3.79 and 4.60. The pH values of soy sauces C4, C5, C6, C8, TH3, Ch6, V1, and V4 were lower than the standard of Institute of Standard of Cambodia. Some soy sauces had a low pH because of the food additives or the soy sauces are produced from acid hydrolysis without a pH adjustment to an appropriate pH of soy sauce [14]. Among all 42 samples tested, all data were significantly different (p<0.05).

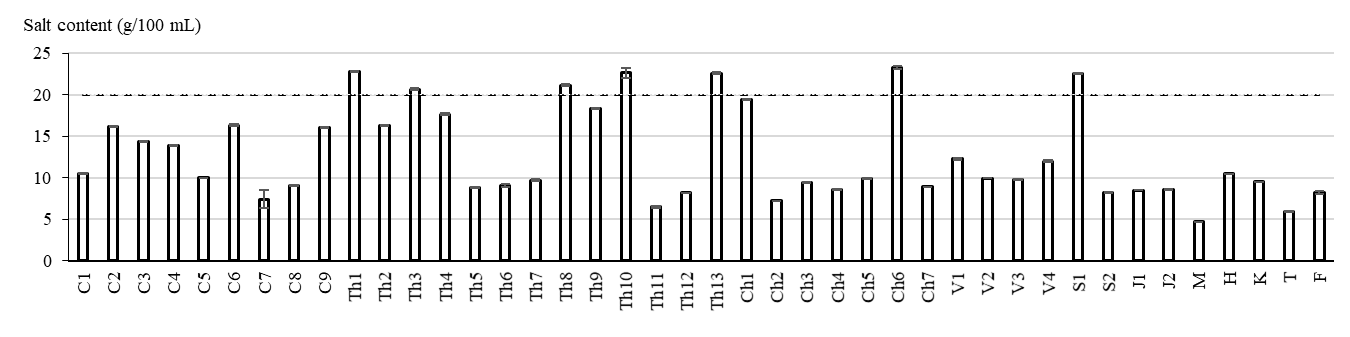

3.2 Salt content of soy sauces sold in the markets

The salt is an essential ingredient used in soy sauce fermentation. A good fermented soy sauce should contain 18% to 20% salt [14]. As shown in figure 2, out of 42 soy sauce samples, "M" soy sauce had a salt content of only 4.7 g/100 mL. With an amount meager, this product must add a food preservative to ensure safety and a longer shelf life. Salt-reduced soy sauce is produced by dilution or electrodialysis to provide a good quality product. Making soy sauce like this will cost a lot of money [19]. While Ch6 has a salt content of 23.27 g/100mL, this amount is very high and over the Cambodian soy sauce standard (CS:066, 2012). Consumption of too much sodium is not suitable for health, especially for someone who suffers from heart disease, hypertension, and kidney disease [8]. Based on the National Institute of Standards of Cambodia, the maximum salt in soy sauce is not over 20%. Among 42 soy sauce samples, only seven samples that had a high amount of salt, over 20%. And all 42 samples' results differed significantly (p<0.05).

Figure 1: pH of soy sauces sold in Cambodian markets. The alphabet codes (C, Th, Ch, V, S, J, M, H, K, T, and F) represent: (Cambodia, Thailand, Vietnam, Singapore, Japan, Malaysia, Hong Kong, Korea, Taiwan, and French), respectively. The code number is used to differentiate soy sauces. Based on Cambodia’s soy sauce standards (CS 066:2011), soy sauce has pH between 4.2 and pH 4.8. All pH values of soy sauce samples data were significantly different (p<0.05).

Figure 2: Salt content of soy sauces sold in Cambodian markets. The alphabet codes (C, Th, Ch, V, S, J, M, H, K, T, and F) represent: (Cambodia, Thailand, Vietnam, Singapore, Japan, Malaysia, Hong Kong, Korea, Taiwan and French), respectively. The code number is used to differentiate soy sauces. Based on Cambodia’s soy sauce standard, soy sauce has salt content equal to or less than 20 [g/100mL]. The results of salt content of all of 42 samples were significantly different (p<0.05).

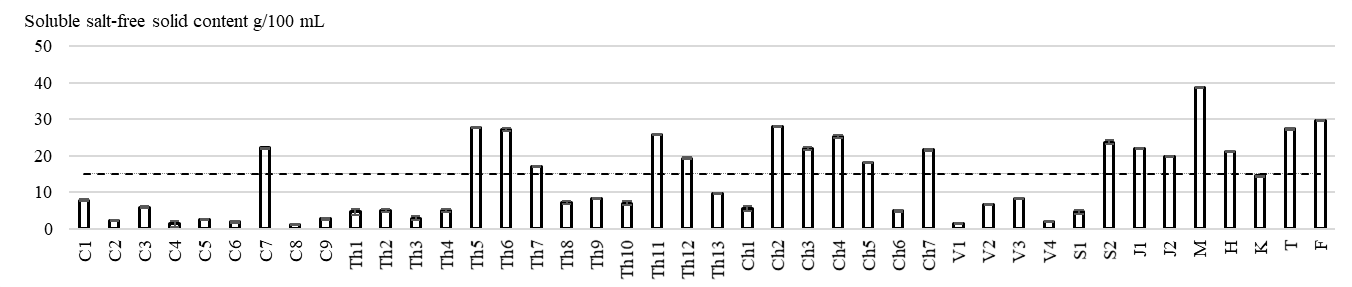

Figure 3: Soluble salt-free solid content of soy sauces sold in Cambodian markets. The alphabet codes (C, Th, Ch, V, S, J, M, H, K, T, and F) represent (Cambodia, Thailand, Vietnam, Singapore, Japan, Malaysia, Hong Kong, Korea, Taiwan, and French), respectively. The code number is used to differentiate soy sauces. Based on Cambodia’s soy sauce standards (CS 066:2011), soy sauce has soluble salt-free solid equal to or greater than 15 [g/100 mL]. All 42 samples' results were significantly different (p<0.05).

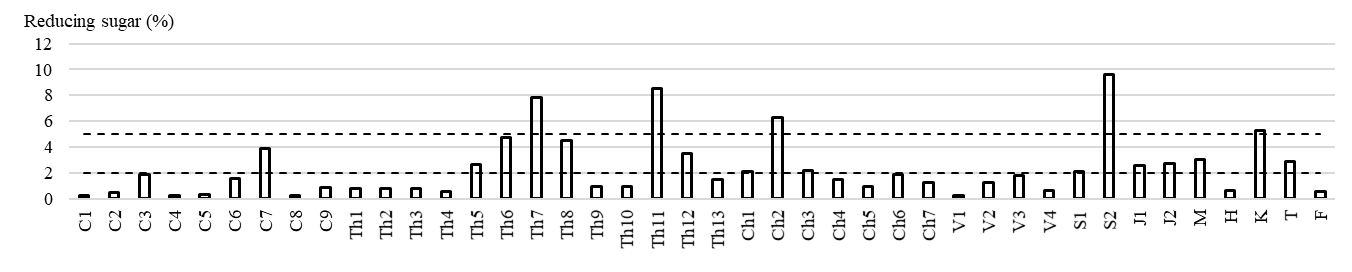

Figure 4: Reducing sugars of soy sauces sold in Cambodian markets. The alphabet codes (C, Th, Ch, V, S, J, M, H, K, T, and F) are represented: (Cambodia, Thailand, Vietnam, Singapore, Japan, Malaysia, Hong Kong, Korea, Taiwan, and France), respectively. The code number is used to differentiate soy sauces. Based on the Industrial production of soy sauce (Luh, 1995), soy sauce has reduced sugar between 2 [g/100 mL] and 5 [g/100 mL]. The reducing sugars of all 42 samples were significantly different (p<0.05).

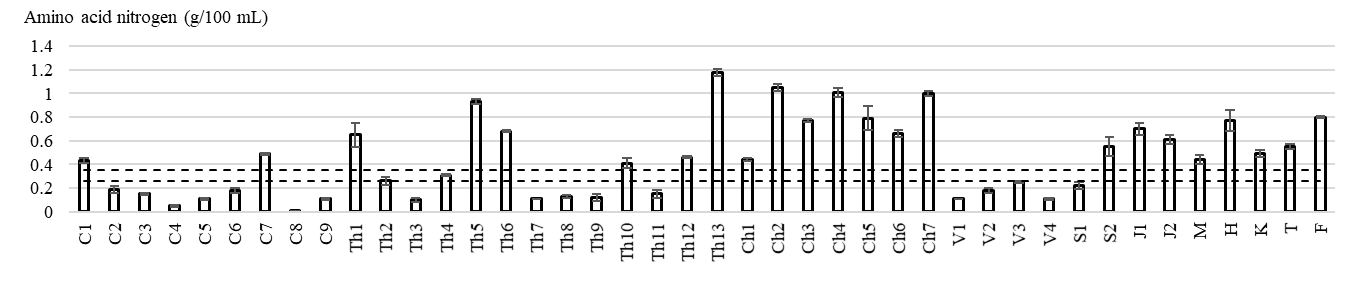

Figure 5: Amino acid nitrogen of soy sauces sold in Cambodian markets. The alphabet codes (C, Th, Ch, V, S, J, M, H, K, T, and F) represent: (Cambodia, Thailand, Vietnam, Singapore, Japan, Malaysia, Hong Kong, Korea, Taiwan, and French), respectively. The code number is used to differentiate soy sauces. Based on Cambodia’s soy sauce standards (CS 066:2011), grades two and one have amino nitrogen 0.26 and 0.35 [g/100 mL], respectively. The results of amino acid nitrogen of all 42 samples were significantly different (p<0.05).

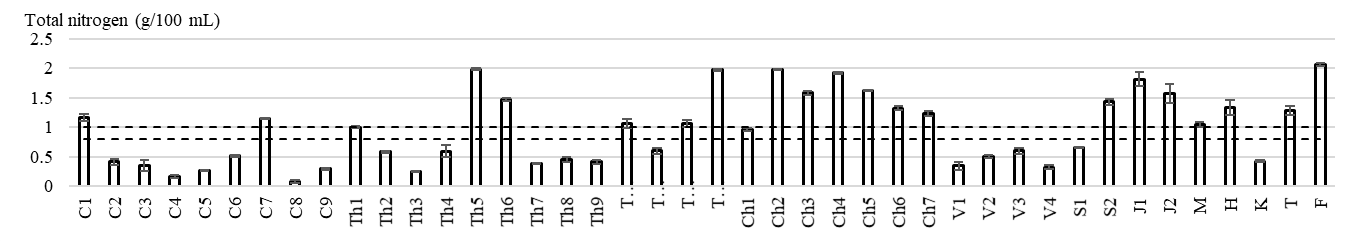

Figure 6: Total nitrogen of soy sauces sold in Cambodian markets. Total nitrogen in soy sauce samples. The alphabet codes (C, Th, Ch, V, S, J, M, H, K, T, and F) represent: (Cambodia, Thailand, Vietnam, Singapore, Japan, Malaysia, Hong Kong, Korea, Taiwan, and French), respectively. The code number is used to differentiate soy sauces. Based on Cambodia’s soy sauce standards (CS 066:2011), light soy sauce grades two and one have total nitrogen 0.8 and 1 [g/100 mL], respectively. The results of all 42 samples were significantly different (p<0.05).

3.3 Soluble salt-free solid content of soy sauces sold in the markets

As shown in figure 3, the lowest amount of soluble salt-free solid content was found in sample C8 (1.21±0.09 g/100mL), while the highest was found in sample M (38.65 ± 0.14 g/100ml). There were 18 samples with the amount of soluble salt-free solid content bigger than 15. According to the Institute of Standards of Cambodia, soy sauces are divided into dark and light. Light soy sauce has a soluble salt-free solid content of about 15 to 18 g/100 mL, and dark soy sauce has a soluble salt-free solid content of about 22 to 44 g/100 mL. The high amount of soluble salt-free solid content is also an indicator of the quality of fermented soy sauce, and it is an important parameter reflecting the quality, significant nutrition matters, and favor for commercial soy sauce [20]. According to the National Food Safety Standards of China, for fermented soy sauce (GB 18186-2000), the premium high salt soy sauce must have soluble salt-free solid content higher or equal to 15 g/100 mL, and the premium low salt must have the soluble salt free solid content higher or equal to 20 g/100 mL. Thus, the soy sauce with a soluble salt-free solid content equal to or above 15 g/100 mL could indicate good fermentation. And all 42 samples’ results differed significantly different (p<0.05).

3.4 Reducing sugars of soy sauces sold in the markets

Reducing sugars are very important for making a good taste and quality soy sauce, and they have about 2 to 5% in a good quality soy sauce[14]. As shown in Figure 4, among 42 soy sauce samples, sample C8 had the lowest reducing sugars with a total amount of 0.21 ± 0.01%, while the highest reducing sugars were found in sample S2 with 9.57 ± 0.06 %. By the way, there were only 12 samples found in the range of 2 to 5%. According to previous research, soy sauce has around 50 kinds of sugars contributing to the sweet taste of soy sauce [21]. Reducing sugars is crucial for making a pleasant smell while acting with amino acids when cooking. Soy sauce also has reducing sugars and is a carbohydrate source for yeast and other bacteria. The Maillard reaction occurred within the reaction between reducing sugars and amino acids. Not all of the compounds produced from the Maillard reaction are always good for human health; fortunately, soy sauce has been found to inhibit the formation of some dangerous substant produced from the Maillard reaction, such as acrylamide, which is possibly the carcinogen during the Maillard reaction [22-24]. The reducing sugars of all 42 samples differed significantly (p<0.05).

3.5 Total nitrogen of soy sauces sold in the markets

Total nitrogen is one of the parameters reflecting the quality of soy sauce, and it allows us to estimate the nutrition, such as amino acids and protein [14,25]. According to the Institute of Standards of Cambodia, soy sauce must have at least a total nitrogen of 0.8%, as shown in figure 6. It showed that 22 soy sauce samples had a nitrogen greater than 0.8 g/100 mL. The total nitrogen and amino nitrogen were used as indicators to show the effect of fermentation. By the way, sample C8 has a very low total nitrogen (0.08 ±0.02 g/100mL); it may be the fermentation that was not good, a short period of fermentation time, or the digestibility of soybeans was not done well, most of this soy sauce could be made from excessive dilution. Furthermore, the results of total nitrogen of all 42 samples were significantly different (p<0.05).

3.6 Amino acid nitrogen content of soy sauces sold in the markets

Amino nitrogen is While Koji incubation and moromi fermentation, Aspergillus oryzae and lactic acid bacteria produced some protease to break down the protein into amino acids [26-28]. Amino acid is very important for improving taste [29]. As shown in figure 5, among 42 soy sauce samples, 23 soy sauces had amino nitrogen greater than 0.26 g/100 mL, and sample Th13 had an amino nitrogen of 1.18 ± 0.17 g/100 mL higher than other samples. However, sample C8 had only amino nitrogen of 0.01 g/100 mL which was lower than the other samples. According to the Institute of Standards of Cambodia, the amino nitrogen in soy sauces must be equal to or greater than 0.26 g/100 mL (CS 066:2011). In addition, the results of amino acid nitrogen of all 42 samples were significantly different (p<0.05).

3.7 Microbiological quality of soy sauces sold in the markets

The total viable count and total halophile yeast were also indicators of the microbiological quality of soy sauce. Halophilic yeasts tolerate high salt concentrations and low pH [30,31]. As shown in table 1, three samples were found to have the presence of halophilic yeast. The sample TH5 had more halophilic yeast than other samples, followed by samples C6 and C2. The presence of halophilic yeasts in the samples could be from the lack of hygienic practice in the production, pasteurizing, or sterilization. The halophile yeasts could deteriorate soy sauce quality, giving off an offensive odor and forming a thin pellicle during long-term storage [15]. To inhibit the growth of the yeasts, sodium benzoate has been applied in soy sauce to prevent the development of yeast regardless of their effects on human health [1]. According to the Institute of Standards of Cambodia, halophilic yeasts must not be in soy sauce products.

|

Soy sauce sample |

Total viable count (CFU/mL) |

Total halophile yeast (CFU/mL) |

|

C1 |

4 |

ND |

|

C2 |

1.6 ×101 |

1.1× 102 |

|

C3 |

2.4×101 |

ND |

|

C4 |

ND |

ND |

|

C5 |

6 |

ND |

|

C6 |

ND |

2×101 |

|

C7 |

4.0×101 |

ND |

|

C8 |

ND |

ND |

|

C9 |

ND |

ND |

|

Th1 |

2.7×102 |

ND |

|

Th2 |

9 |

ND |

|

Th3 |

1.4×102 |

ND |

|

Th4 |

ND |

ND |

|

Th5 |

ND |

3.5×102 |

|

Th6 |

1.4×101 |

ND |

|

Th7 |

3×101 |

ND |

|

Th8 |

ND |

ND |

|

Th9 |

ND |

ND |

|

Th10 |

4.9×101 |

ND |

|

Th11 |

4.9×101 |

ND |

|

Th12 |

2.4×102 |

ND |

|

Th13 |

4.8×101 |

ND |

|

Ch1 |

ND |

ND |

|

Ch2 |

4.4×101 |

ND |

|

Ch3 |

9×101 |

ND |

|

Ch4 |

2×101 |

ND |

|

Ch5 |

5 |

ND |

|

Ch6 |

ND |

ND |

|

Ch7 |

ND |

ND |

|

V1 |

ND |

ND |

|

V2 |

ND |

ND |

|

V3 |

ND |

ND |

|

V4 |

ND |

ND |

|

S1 |

1.6 ×103 |

ND |

|

S2 |

ND |

ND |

|

J1 |

ND |

ND |

|

J2 |

ND |

ND |

|

M |

1.2×102 |

ND |

|

H |

1.2×103 |

ND |

|

K |

ND |

ND |

|

T |

1.4×103 |

ND |

|

F |

ND |

ND |

ND: Not detected

Table 1: Total viable count and total halophile yeast of soy sauces sold in Cambodian markets.

The total viable count using pour plate method was used to enumerate aerobic and facultative anaerobic bacteria in food [29]. According to the National Standard of the People's Republic of China, the total bacterial colonies should be less than 5,000 CFU/mL (GB 2717-2018). As shown in table 1, the highest bacteria grown on sample S1 was 1.6 × CFU/mL. However, all of the samples had total plate counts lower than 5×103 CFU/mL, and total viable count was not detected in some samples.

4. Conclusion

In conclusion, 8 samples among 42 soy sauce samples were found to be high-quality soy sauces (grade 1) as indicated in the Institute of Standards of Cambodia. Among 9 Cambodian soy sauces sold in the markets, only one brand that was classified as grade I. Amino acid nitrogen is an essential indicator of the quality of fermented soy sauce and only 64% of soy sauces sold in the Phnom Penh markets had amino acid nitrogen as indicated in Institute of Standards of Cambodia. On the other hand, there were only 22.22% of Cambodian soy sauces which had amino acid nitrogen as indicated in soy sauce standard. Thus, the quality of Cambodia soy sauces should be improved. Moreover, there were three soy sauces with the presence of halophilic yeasts, including samples C2, C7, and Th5. For further research, the volatile compounds, 3-monochloropropane diol (3-MCPD), and the development of high-quality Cambodian soy sauce with benefits for human health and competitive prices should be investigated.

Acknowledgement

The work was funded by Cambodia Higher Education Improvement Project (Credit No. 6221-KH).

References

- Leboffe MJ, Pierce BE. Microbiology: Laboratory Theory and Application, Essentials - Michael J. Leboffe, Burton E. Pierce - Google Bøker. Morton Publishing Company (2006).

- Huang Z, Feng Y, Zeng J, et al. Six categories of amino acid derivatives with potential taste contributions: a review of studies on soy sauce. Critical Reviews in Food Science and Nutrition 63 (2023): 365.

- Gao X, Zhao H, Feng Y, et al. A comparative study on physicochemical properties of Chinese-type soy sauces prepared using pure koji and mixed kojis. Afr J Biotechnol 9 (2010): 6740-6747.

- García A, Pérez LM, Piccirilli GN, et al. Evaluation of antioxidant, antibacterial and physicochemical properties of whey protein-based edible films incorporated with different soy sauces. LWT 117 (2020): 659.

- Kurzer MS. Soy consumption for reduction of menopausal symptoms. Inflammopharmacology 16 (2008): 227-229.

- Kwon DY, Daily JW, Kim HJ, et al. Antidiabetic effects of fermented soybean products on type 2 diabetes. Nutr Res 30 (2010): 1-13.

- Theary C. Fish sauce, soy sauce, and vegetable oil fortification in Cambodia: Where do we stand to date?. Food Nutr Bull 34 (2013): 352.

- Yong FM, Wood BJB. Microbiology and Biochemistry of Soy Sauce Fermentation. Adv Appl Microbiol 17 (1974): 157-194.

- Diez-Simon C, Eichelsheim C, Mumm R, et al. Chemical and Sensory Characteristics of Soy Sauce: A Review. J Agric Food Chem 68 (2020): 11612-11630.

- Gao X. Characterization of the aroma-active compounds in black soybean sauce, a distinctive soy sauce. Food Chem 364 (2021): 130334.

- Xu J, Jin F, Hao J, et al. Preparation of soy sauce by walnut meal fermentation: Composition, antioxidant properties, and angiotensin-converting enzyme inhibitory activities. Food Sci Nutr 8 (2020): 1665-1676.

- Aaslyng MD, Martens M, Poll L, et al. Chemical and Sensory Characterization of Hydrolyzed Vegetable Protein, a Savory Flavoring. J Agric Food Chem 46 (1998): 481-489.

- Guo M. Soy food products and their health benefits. Functional Foods 28 (2009): 237-277.

- Luh BS. Industrial production of soy sauce. J Ind Microbiol 14 (1995): 467-471.

- Retnaningsih C, Meiliana, Surya, et al. Physicochemical and sensory characteristics of soy sauce substituted with pigeon pea (Cajanus cajan (Linn.)). IOP Conf Ser Earth Environ Sci 102 (2018): 012047.

- Kim JS, Lee YS. A study of chemical characteristics of soy sauce and mixed soy sauce: Chemical characteristics of soy sauce. European Food Research and Technology 227 (2008): 933-944.

- Devanthi PVP, Gkatzionis K. Soy sauce fermentation: Microorganisms, aroma formation, and process modification. Food Research International 120 (2019): 364-374.

- Silva FVM, Gibbs P. Target Selection in designing pasteurization processes for shelf-stable high-acid fruit products 44 (2010): 353-360.

- Luo J, Ding L, Chen X, et al. Desalination of soy sauce by nanofiltration. Sep Purif Technol 66 (2009): 429-437.

- Gao X. Enhancing the taste of raw soy sauce using low intensity ultrasound treatment during moromi fermentation. Food Chem 298 (2019): 124928.

- Zhao G, Feng Y, Hadiatullah H, et al. Chemical Characteristics of Three Kinds of Japanese Soy Sauce Based on Electronic Senses and GC-MS Analyses. Front Microbiol 11 (2021): 579808.

- Dills WL. Protein fructosylation: Fructose and the Maillard reaction. American Journal of Clinical Nutrition 58 (1993): 195.

- Zhu Y, An B, Luo Y, et al. Influence of Seasonings and Spice Essential Oils on Acrylamide Production in a Low Moisture Model System. Foods 11 (2022): 638.

- Klaunig JE. Acrylamide Carcinogenicity. J Agric Food Chem 56 (2008): 5984-5988.

- Luo T, Xie Y, Dong Y, et al. Quality assessment of soy sauce using underivatized amino acids by capillary electrophoresis. Int J Food Prop 20 (2015): S3052-S3061.

- Kieliszek M, Pobiega K, Piwowarek K, et al. Characteristics of the Proteolytic Enzymes Produced by Lactic Acid Bacteria. Molecules 26 (2021): 7.

- Sugiyama S. Selection of micro-organisms for use in the fermentation of soy sauce. Food Microbiol 1 (1984): 339-347.

- Zhao G, Ding LL, Yao Y, et al. Extracellular proteome analysis and flavor formation during soy sauce fermentation. Front Microbiol 9 (2018): 406322.

- Alharbi NS. Optimization of glutamic acid production by Corynebacterium glutamicum using response surface methodology. J King Saud Univ Sci 32 (2020): 1403-1408.

- O’toole DK. The role of microorganisms in soy sauce production in advances in applied microbiology. Academic Press Inc., 12 (2019): 45-113.

- Ito K, Matsuyama A. Koji Molds for Japanese Soy Sauce Brewing: Characteristics and Key Enzymes. Journal of Fungi 7 (2021): 658.