Comparative study of variants of Koura-Koura Production Technology in Burkina Faso

Article Information

Yamkaye Aïcha Sawadogo1, Adama Sawadogo1, Lydie Moreau2, Blaise Waongo1, Aly Savadogo1*

1Department of Biochemistry and Microbiology, Laboratory of Applied Biochemistry and Immunology, University Joseph KI-ZERBO, 03 BP 7021 Ouagadougou 03, Burkina Faso

2University of Applied Sciences and Arts Western Switzerland Valais (HES-SO Valais-Wallis) Institute of Life Technologies, Sion, Switzerland, Route du Rawyl 64, 1950 Sion

*Corresponding Author: Aly Savadogo, Department of Biochemistry and Microbiology, Laboratory of Applied Biochemistry and Immunology, University Joseph KI-ZERBO, 03 BP 7021 Ouagadougou 03, Burkina Faso

Received: 18 March 2021; Accepted: 29 March 2021; Published: 31 March 2021

Citation: Citation: Yamkaye Aïcha Sawadogo, Adama Sawadogo, Lydie Moreau, Blaise Waongo, Aly Savadogo. Comparative Study of Variants of Koura-Koura Production Technology in Burkina Faso. Journal of Food Science and Nutrition Research 4 (2021): 50-56.

Share at FacebookAbstract

Context: The koura-koura production technology is know-how transmitted from generation to generation and goes through several stages.

Methods: Investigations with 15 female producers have allowed the implementation of variants of the production technology.

Results: The investigations showed that there are three variants of seed preparation, two variants of depellicating, and three variants of de-oiling and shaping. The selection of the best variants allowed the implementation of less time-consuming production technology with little contamination.

Conclusion: The variants of the koura-koura production technology allow several production diagrams with variations in the finished product.

Keywords

Variant, Production, Technology, Koura-Koura, Burkina Faso

Variant articles; Production articles; Technology articles; Koura-Koura articles; Burkina Faso articles

Variant articles Variant Research articles Variant review articles Variant PubMed articles Variant PubMed Central articles Variant 2023 articles Variant 2024 articles Variant Scopus articles Variant impact factor journals Variant Scopus journals Variant PubMed journals Variant medical journals Variant free journals Variant best journals Variant top journals Variant free medical journals Variant famous journals Variant Google Scholar indexed journals Production articles Production Research articles Production review articles Production PubMed articles Production PubMed Central articles Production 2023 articles Production 2024 articles Production Scopus articles Production impact factor journals Production Scopus journals Production PubMed journals Production medical journals Production free journals Production best journals Production top journals Production free medical journals Production famous journals Production Google Scholar indexed journals Technology articles Technology Research articles Technology review articles Technology PubMed articles Technology PubMed Central articles Technology 2023 articles Technology 2024 articles Technology Scopus articles Technology impact factor journals Technology Scopus journals Technology PubMed journals Technology medical journals Technology free journals Technology best journals Technology top journals Technology free medical journals Technology famous journals Technology Google Scholar indexed journals Koura-Koura articles Koura-Koura Research articles Koura-Koura review articles Koura-Koura PubMed articles Koura-Koura PubMed Central articles Koura-Koura 2023 articles Koura-Koura 2024 articles Koura-Koura Scopus articles Koura-Koura impact factor journals Koura-Koura Scopus journals Koura-Koura PubMed journals Koura-Koura medical journals Koura-Koura free journals Koura-Koura best journals Koura-Koura top journals Koura-Koura free medical journals Koura-Koura famous journals Koura-Koura Google Scholar indexed journals Burkina Faso articles Burkina Faso Research articles Burkina Faso review articles Burkina Faso PubMed articles Burkina Faso PubMed Central articles Burkina Faso 2023 articles Burkina Faso 2024 articles Burkina Faso Scopus articles Burkina Faso impact factor journals Burkina Faso Scopus journals Burkina Faso PubMed journals Burkina Faso medical journals Burkina Faso free journals Burkina Faso best journals Burkina Faso top journals Burkina Faso free medical journals Burkina Faso famous journals Burkina Faso Google Scholar indexed journals Peanuts articles Peanuts Research articles Peanuts review articles Peanuts PubMed articles Peanuts PubMed Central articles Peanuts 2023 articles Peanuts 2024 articles Peanuts Scopus articles Peanuts impact factor journals Peanuts Scopus journals Peanuts PubMed journals Peanuts medical journals Peanuts free journals Peanuts best journals Peanuts top journals Peanuts free medical journals Peanuts famous journals Peanuts Google Scholar indexed journals groundnut articles groundnut Research articles groundnut review articles groundnut PubMed articles groundnut PubMed Central articles groundnut 2023 articles groundnut 2024 articles groundnut Scopus articles groundnut impact factor journals groundnut Scopus journals groundnut PubMed journals groundnut medical journals groundnut free journals groundnut best journals groundnut top journals groundnut free medical journals groundnut famous journals groundnut Google Scholar indexed journals pancakes articles pancakes Research articles pancakes review articles pancakes PubMed articles pancakes PubMed Central articles pancakes 2023 articles pancakes 2024 articles pancakes Scopus articles pancakes impact factor journals pancakes Scopus journals pancakes PubMed journals pancakes medical journals pancakes free journals pancakes best journals pancakes top journals pancakes free medical journals pancakes famous journals pancakes Google Scholar indexed journals cakes articles cakes Research articles cakes review articles cakes PubMed articles cakes PubMed Central articles cakes 2023 articles cakes 2024 articles cakes Scopus articles cakes impact factor journals cakes Scopus journals cakes PubMed journals cakes medical journals cakes free journals cakes best journals cakes top journals cakes free medical journals cakes famous journals cakes Google Scholar indexed journals

Article Details

1. Introduction

Peanuts are oilseed that is grown in all tropical and subtropical regions of the world [1]. It is produced mainly in Asia, Africa, and the Americas. Global production of shelled groundnut amounted to more than 47 million tons in 2017 and Africa is the second-largest producer with 13.94% of global production [2]. In Burkina Faso peanut is the second largest cash crop and its production was 328778 tons in 2018 [3]. It occupies an important place in society and contributes significantly to Gross Domestic Product (GDP) and household agricultural income. The sector contributes annually to nearly 1.45% of GDP [4]. Peanuts also provide households with 8.8% of total agricultural income and nearly 16% of agricultural monetary income [5]. Peanuts are consumed in several forms: as raw, boiled, or roasted seeds, or in more or less elaborate forms such as butter, dough, flour, and pancakes in Burkina Faso. Peanut processing is a substantial income-generating activity for women [6]. Peanut pancakes (koura-koura) are produced artisanally by women and the production technology differs from one locality to another. Knowledge of these technological variants would allow a better valorization of the koura-koura.

2. Materials and Methods

2.1 Collection of technological data

To gain a better understanding of traditional koura-koura production technologies, investigations were carried out among 15 women producers in the form of a survey. The technological data of the koura-koura were collected using a questionnaire administered by direct interview. A detailed description of the koura-koura production process made it possible to establish variants of the production diagram.

2.2 Data processing

The information collected from the producers was converted into diagram form on the Word software.

3. Results

3.1. Variants of koura-koura production technology

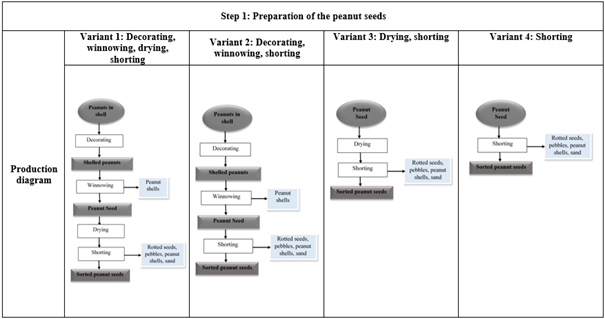

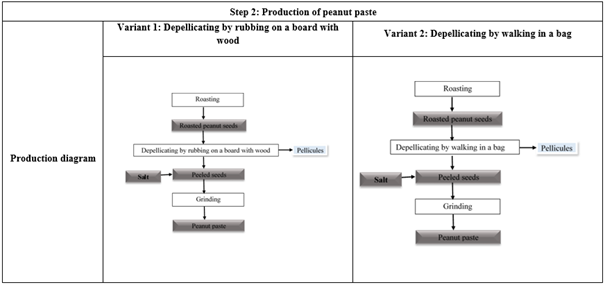

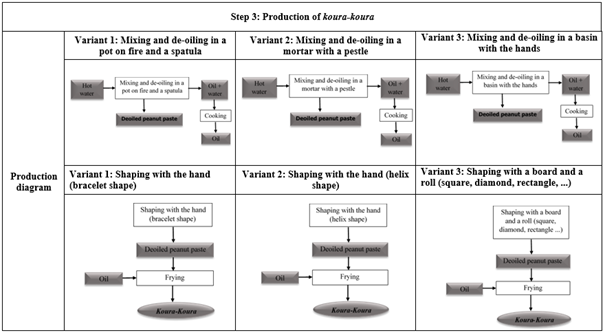

Technological investigations with the women producers have made it possible to establish production diagrams. The unit operations of koura-koura production are identical, with however variations according to the production stages (Figures 1- 3).

Figure 1: Preparation of the peanut seeds.

Figure 2: Production of the peanut paste.

Figure 3: Production of Koura- Koura.

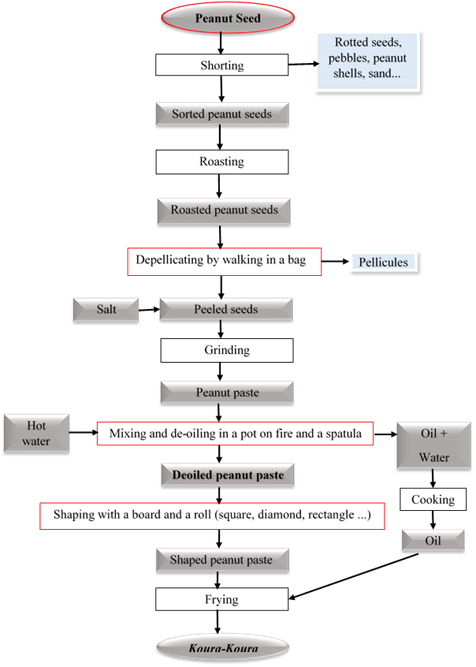

3.2. Koura-koura production diagram from the best variants

A combination of the best variants of each step was used to create a diagram (Figure 4). This diagram took into account the production time and the sanitary quality.

Figure 4: Koura-koura production diagram from the best variants

4. Discussion

4.1 Variants of koura-koura production technology

There are four variations in the preparation of the raw material. The first and the second include the hulling stage to obtain the peanut seeds. In the third and fourth variants, the producers pay directly for the already shelled seeds. The first and the third variant contain a step of drying the peanut seeds. In all the variants, the preparation of the raw material consists of cleaning the peanut seeds to remove all impurities and the cleaning is done in 2 steps. The first step consists of sorting rotten and/or moldy peanut seeds, stones, and other solid waste from high masses. The second step is winnowing the seeds to remove small peanut shells, sand, straw, and other low mass solid wastes. The preparation of peanut seeds is a very important step in the koura-koura production process. It reduces the microbial load by sorting out impurities and rotten seeds and reduces the concentration of aflatoxins by removing moldy seeds. The successful completion of this step will have an impact on the finished product. Indeed, the preparation of the seeds will allow having a finished product without sand and better sanitary quality. Seeds that have already been shelled and no longer dry before roasting [6,7]. However the peanut seeds were roasted before sorting them [8]. This may make sorting difficult and inefficient. Indeed the roasted seeds take on a dark color and make it difficult to differentiate between rotten seeds which are usually dark.

After roasting, the seeds are cooled by spreading them on a plastic bag and removing their skins. There are two variants of depellicating. In the first variant, depellicating consists of cooling the seeds on a plastic bag and pressing them lightly with a grindstone-shaped wood to separate the seeds from the skins. In the second variant, depellicating consists of cooling the peanut seeds on a plastic bag, placing them in a jute bag and trampling the bag to separate the seeds from the skins. Depellicating was performed by pressing the peanut seeds onto a plate with a wood. In both variants, the dehulled seeds are winnowed with a plate to separate the seeds from the husks. The process of depellicating step cannot seen in kluiklui production flow chart and this could influence the quality of the final product. Indeed, this step contributes to the improvement of the organoleptic and sanitary quality of koura-koura by removing the film. After removal of the husk, the peanut seeds with added salt are crushed into fine particles to obtain a fairly thick paste.

The paste obtained undergoes a de-oiling process which consists of separating the oil from the peanut cake. There are three variants of de-oiling. The first consists of putting the peanut paste on low heat in a pot and adding hot water while stirring it with a spatula. The second is to put the peanut paste in a mortar and grind it while adding hot water. The third variation is to put the peanut paste in a bowl and knead it with your hands while adding hot water. The mechanical action associated with heat allows the separation of the miscible (oil+water) from the cake. After separation of the oil from the cake, the miscible is recovered in a pot with a ladle, then heated to evaporate the water and leave the oil. Part of this oil is used to fry the cakes and the other part is sold. Authors [9] do the de-oiling by putting the peanut paste in a basin, kneading it with the hands, and then pressing the paste on a table to separate it from the oil. The cake is then shaped into different shapes according to the variants. For the first and the second variant, the shaping is done manually on an inclined board (for the first) or a plate (for the second) to facilitate the flow of the miscible remaining in the dough. For the third variant, shaping is done by spreading the cake on a board and spreading it with a rolling pin. Different shapes are then cut (square, rectangle, diamond...) with a knife. According to [11] kluiklui is marketed in Benin, particularly in the North (commune of Djougou) where they take the form of cakes, and in the South-East in the Mono (communes of Lokossa and Dogbo) where they take the form of circles or snails. The shaped cakes are put in hot oil to be fried. The cakes are ready when they take on a golden color and rise to the surface of the oil. The patties are drained and cooled after frying.

4.2 Koura-koura production diagram from the best variants

The use of shelled peanut kernels considerably reduces production time. However, it slightly increases the cost of production. Indeed, in West Africa, the price of shelled groundnut varied from 324 to 417 F CFA/kg against 508 to 576 F CFA/kg for shelled groundnut [12]. The drying step before sorting makes the process long and unnecessary. Indeed, roasting in addition to facilitating depellicating and increasing the sensory quality of the peanut seeds reduces their moisture content. It consists of subjecting peanut seeds to a high temperature ranging from 140 °C to 180 °C in a short time [13]. Removal of supprimed peanut seeds from the bag by trampling is faster than rubbing them with wood. It also avoids contact with hands and thus reduces microbiological contamination. De-oiling in a pot over low heat with a spatula reduces the microbial load in koura-koura. Indeed the use of hot water and the heat of the fire allow a reduction of the microbial load. This has reduced the total mesophilic flora from 4.19x105 (peanut paste) to 4.10x105 (de-oiled peanut paste) [14]. Also, this variant is the safest compared to the other two. Indeed, when peanut paste is plundered in the mortar with hot water, there may be splashes that could burn the producer. Also when kneading with the hands these can be burned with the hot water used for de-oiling. The use of the board and the rolling pin for shaping avoid microbiological contamination. The hand is the most important vehicle for the transfer of microorganisms from feces, nose, and skin to food [15]. However, this technique makes it possible to have new forms of koura-koura. This variant may not be readily accepted compared to traditional hand-made variants.

5. Conclusion

The investigation of the koura-koura production technology has led to variants in the three stages of production. There are four variants in the peanut seed preparation stage. The peanut paste production stage has two variants. Finally, the koura-koura production stage has three variants. The choice of the best variants has made it possible to set up a koura-koura production diagram with a reduced production time and a reduced health and safety level.

Acknowledgments

Authors thank their Laboratory (LaBIA), the local direction of scholarship (National Center for Information, School and Professional Orientation and Scholarships of Burkina Faso), and the women who were interviewed in this study for the time.

Conflicts of Interest

No conflicts of interest have been registered on this work to the best of our knowledge.

References

- Novello C, Santamaria C. Food allergy to peanuts. University of Paris XII - Val de Marne (2005): 37.

- Food and Agriculture Organization of the United Nations Statistics Division. (2018).

- Ministry of Agriculture. Evolution of groundnut production (in tons) from 2008 to 2018. (2018).

- Baseline situation of the main agro-sylvo-pastoral and fisheries sectors in Burkina Faso. (2013): 74.

- Analysis of the results of the Burkina Faso survey on household living conditions. Final report (2003): 223.

- Analysis of price incentives for groundnuts in Burkina Faso Series of technical notes. Rome (2015): 45.

- Adjou ES, Codjo BY, Mohamed MS, et al. Occurrence of mycotoxins and associated mycoflora in peanut cake product (kulikuli) marketed in Benin. African Journal of Biotechnology 11 (2012): 14354-14360.

- Emelike NJT, Akusu MO. Proximate Composition and Sensory Properties of “Kuli-Kuli” Produced from the Blends of Groundnut and Cashew Kernel. International Journal of Food Science and Nutrition Engineering. 8 (2012): 1-4.

- Sanya EA, Ahouannou C, Chaffa G, et al. Effects of torrefaction on some physicomechanical and organoleptic characteristics of maize flour blended peanut patties rolled into sticks in Benin. International Journal of Biological and Chemical Sciences 9 (2015): 1440-1458.

- Ayoade F, Adegbite TD. Microbiological screening of street-vended groundnut cake, Kulikuli and natural spices for reducing microbial contamination in the food snack. International Journal of Biological and Chemical Sciences. 10 (2016): 2677-2691.

- Videgla EG, Floquet A, Mongbo R, et al. Links to the origin and specific quality of a product of the food-processing craft industry of Benin - Agonlin's kluiklui. Cahiers Agricultures 24 (2016): 1-8.

- Monthly bulletin on agricultural markets. 9 (2017): 4.

- ACMA-2. Fact sheet: transformation of groundnuts into oilcake. (2019): 7-10.

- Sawadogo YA, Cissé H, Zongo O, et al. Reduction of aflatoxins and microorganisms in the koura-koura produced in Burkina Faso with spices and aromatic leaves. Journal of Food Technology Research 8 (2021): 9-17.

- Sanitary control and management of food handlers. Technical Report Series (1989): 785.