Stabilization and Sensory Evaluation of Cashew Apple Juice (Anacardium occidentale L.) from the Northeast Region in Côte d'Ivoire

Article Information

Adou Marc1*, Tetchi Fabrice Achille1, Adjouman Yao Désiré1,2, Amani N’Guessan Georges1

1Université Nangui Abrogoua, UFR des Sciences et Technologies des Aliments, 02 BP 801 Abidjan 02, Côte d’Ivoire

2Centre Suisse de Recherches Scientifiques en Côte d’Ivoire (CSRS), 01 BP 1303 Abidjan 01, Côte d'Ivoire

*Corresponding Author: Adou Marc, Université Nangui Abrogoua, UFR des Sciences et Technologies des Aliments, Abidjan 02, Côte d’Ivoire

Received: 06 May 2019; Accepted: 16 May 2019; Published: 20 May 2019

Citation: Adou Marc, Tetchi Fabrice Achille, Adjouman Yao Desire, Amani N Guessan Georges. The Stabilization and Sensory Evaluation of Cashew Apple Juice (Anacardium occidentale L.) from the Northeast Region in Cote d Ivoire. Journal of Food Science and Nutrition Research 2 (2019): 108-127.

Share at FacebookAbstract

The aim of this work is to study the stability under predefined conditions of cashew nut juice and its sensory evaluations. Cashew apple juices have a pleasant taste and are generally marketed as frozen pulp, juice and nectar. This study examined the stability of the different samples of pasteurized cashew apple juice at 75°C/5 min and 90°C/30s and stored at different temperatures. Parameters such as pH, acidity, Refractometric Dry Extract (ESR), total sugar content, reducing sugars, vitamin C and microbiological analysis were determined on the juices. Pasteurization scales and storage time have shown a significant influence on the evolution of these parameters. Thus, the evolution of pH, acidity and ESR is due to the degradation of total sugars, reducing sugars and vitamin C used as substrates in the various reactions. Of these substrates studied, vitamin C is the compound that degrades most rapidly. Microbiological analysis also revealed the absence of total and fecal coliforms. The sensory evaluation showed that physicochemical and to a lesser extent microbiological variations in the environment did not influence the assessment of the juice samples. In short, the pasteurization rate of 75°C/5 min and the storage time for 5 days can be retained for a better preservation of the physicochemical characteristics. Thermal treatment, notwithstanding the degradation caused by vitamin C, appears to be an effective way of preserving cashew apple juice.

Keywords

Cashew apple, Cashew apple juice, Pasteurized juice, Stabilization, Vitamin C

Article Details

1. Introduction

The cashew tree (Anacardium occidentale L.) comes from some countries in Latin America and can be found in West Indies. It has been naturalized in several tropical countries in Asia and Africa, including Côte d'Ivoire [1]. The nut (real fruit) is the most important product of the cashew tree. The cashew tree has now become a booming cash crop and represents a great opportunity for Africa in terms of exporting its nuts [2]. This tree was introduced in the 1960s and 1970s in northern Côte d'Ivoire, a region which is considered as a serious cattle breeder [3]. Over the last 5 years, that is (2013-2017), cashew nut production in Côte d'Ivoire has moved from 513,000 tonnes to 711,000 tonnes [4]. According to FAO data, the cashew nut production in Côte d'Ivoire is estimated at 22% of worldwide production and represents 750 000 tonnes in 2018 [4]. This achievement in cashew nut production has made Côte d'Ivoire the world's leading producer and exporter in this domain. Currently and mostly produced for its nuts, cashew tree also provide people with its apples (pseudo fruit). It is an enlarged stalk to which the nut is attached. The juicy cashew apple has a pleasant flavor and is generally marketed as frozen pulp, juice and nectar [5].

Cashew apples have been in the center of multitudinous scientific studies seeking to improve microbiological, organoleptic, nutritional quality and curative potential [2, 6-9]. It has the nutritional qualities for its richness in vitamin C and magnesium. It also has a technological interest thanks to its edible part between 85% and 100% with a juicy and sweet flesh, free of pips or stones [10]. In addition to that, cashew apple juice is 5 times richer in vitamin C than orange juice and 10 times richer in vitamin C than pineapple juice [11-13]. In health domain, cashew apple juice is considered as an excellent remedy for sore throats and chronic dysentery [14]. Phenolic compounds present in its breast provide effective protection against cardiovascular disease and certain cancers [15-16]. Despite its high nutritional potential, most of its production is abandoned at harvest sites. In fact, some taboos make people believe in a higher risk of food poisoning or even death due to the consumption of cashew nuts or their derivatives, milk and dairy products [2, 17-19]. Ivorian cashew apple production in 2015 was estimated at more than 6 million tonnes but was not exploited [20]. A better use of cashew apples, a by-product of walnut production will help to stabilize cashew tree exploitation. Besides, it will create new jobs and will hopefully help fight unemployment in Côte d'Ivoire [21]. Based on the use of many fruits, the main possible recovery method is to transform it into juice. However, in the case of cashew apples, this transformation process is confronted to three major obstacles. Firstly, there is the astringency of the juice due to the presence of condensed tannins. Secondly, we have the high thermo-sensitivity of the product both in nutrition and sensory aspects. Finally, we have the presence of sugar responsible for Maillard reactions during heat treatment [20].

Despite the fact that cashew apple juice is made of important nutrients [8, 13, 22-23], it has one weakness: its high alterability. This condition requires special maintenance in terms of pasteurization and storage [24]. Pasteurization deals with heat treatment to a temperature ranked among 60 and 100°C. In fact, it aims at destroying all non-spore-forming pathogenic microorganisms and, more significantly seeks at reducing the vegetative flora present in a product. It minimizes the biological activities of a product while preserving its organoleptic and nutritional characteristics. The objective of this work is therefore to study the stability under predefined conditions of cashew apple juice and their sensory evaluations.

2. Materials and Methods

2.1 Material

The plant material consists in yellow and red cashew apple varieties from Bondoukou which is a Northeast production area in Côte d'Ivoire. Ripe cashew apples, fallen from the trees, were collected from cashew nut plantations during the walnut harvest period (March-May). These were sorted in order to only retain the intact ones, i.e. without any injury or rot. Then, they were transported to the laboratory. During the travelling time, they were put in coolers equipped with ice accumulators.

2.2 The pasteurization process

The pasteurization of cashew apple juice was carried out according to the method of Diop et al. [25]. The juices from the different cashew apples were distributed in glass containers (100 mL bottles). Using a water bath with thermostat and cover, the pasteurization temperatures were displayed. When the ideal temperature was stabilized, the bottles containing the cashew apple juice were immersed in the water bath for the predetermined pasteurization time. Thus, cashew apple juice was pasteurized according to two pasteurizations’ scales which are 75°C for 5 min and 90°C for 30s. Pasteurized juice samples were stored at various temperatures to monitor the evolution of physicochemical and microbiological parameters. Storage temperatures are: laboratory temperature (22°C ± 1°C), refrigerator temperature (5°C ± 1°C) and freezer temperature (-18°C ± 1°C).

2.3 pH determination

The pH of apple juice was determined using a pH meter (pH meter C861, Consort, bio block, Belgium) according to the AOAC method [26]. The instrument was calibrated using two buffer solutions at pH 7.0 and 4.0 and this was systematically done before pH measuring. The measurement was made by immersing the electrode in 5 mL of sample and the reading is repeated three times.

2.4 Storage conditions and metered physicochemical parameters

Pasteurized cashew apple juice stored under different conditions was analyzed at predefined interval times (Table 1). The physicochemical parameters sought include total sugars, reducing sugars and vitamin C, which are substrate indicators. Then we have pH, acidity, ESR, which are the parameters for the environmental evolution. At the microbiological level, the health markers, that is, coliforms (total and thermo-tolerant) and mesophilic aerobic germs (GAM) were researched and quantified.

|

Pasteurization scale |

Unit |

Storage temperature |

Storage time |

||||

|

T1 |

T2 |

T3 |

T4 |

T5 |

|||

|

75°C/5 min |

Hours |

22°C |

5 |

10 |

15 |

20 |

24 |

|

Days |

5°C |

1 |

2 |

3 |

4 |

5 |

|

|

Days |

-18°C |

20 |

40 |

60 |

80 |

100 |

|

|

90°C/30 s |

Hours |

22°C |

5 |

10 |

15 |

20 |

24 |

|

Days |

5°C |

1 |

2 |

3 |

4 |

5 |

|

|

Days |

-18°C |

20 |

40 |

60 |

80 |

100 |

|

Table 1: Summary of storage conditions for pasteurized juice samples.

2.5 Microbiological analyses

2.5.1 Research of mesophilic aerobic germs (GAM): The search for mesophilic aerobic germs was performed on PCA (Plant Count Agar) agar. The stock solution was obtained by diluting 10 mL of cashew apple juice in 90 mL of sterile buffered peptone water in an Erlenmeyer. The mixture is homogenized for 30 to 60 s. Thus, the stock solution obtained was diluted to 10-2 and 10-3. The enumeration of mesophilic aerobic germs was carried out using the technique of seeding the mass with PCA agar or standard canned agar at 30°C after 72 ± 3 h incubation. The number of colonies obtained is expressed as a function of the corresponding dilution with reference to NF ISO 4833 and NF V 08-051.

2.5.2 Research and enumeration of Total and Thermo-tolerant Coliforms: The search and enumeration of total coliforms were performed on LRV agar at 30°C for 24 ± 1 h incubation time according to NF ISO 4832. While using a sterile pipette, 10 mL of cashew nut juice was collected and dissolved in an Erlenmeyer containing 90 mL of buffered peptone water. The mixture is homogenized for 30 to 60 s. Thus, the stock solution obtained is diluted to 10-2 and 10-3. The search for total and heat-tolerant coliforms was performed using the technique of inoculation into the mass of canned LRV agar at 30°C after 72 ± 3 h incubation and at 44°C for heat-tolerant coliforms. For the reading, red colonies with a diameter greater than or equal to 0.5 mm were counted and the result was expressed taking into account the dilution.

2.6 Sensory analysis of cashew apple juice

The sensory evaluation of the organoleptic characteristics of apple juice samples was carried out at the “Laboratoire National de la Santé Publique” (LNSP) in Abidjan, Côte d'Ivoire. A hedonic test on a linear 9-point scale (Table 2) assessed the degree of appreciation of organoleptic characteristics. This study was carried out using the method described by Stone and Sidel [27]. It was applied more specifically to cashew nut juice by Talasila et al. [28].

Table 2: 9-point hedonic scale.

2.6.1 Tasting panel: A thirty (30) people panel was set up. This panel was made up of people who had not been trained in the chosen characteristics. It was therefore suitable to test the acceptability of the different samples of pasteurized apple juice (75°C/5 min and 90°C/30 s) and stored at different storage temperatures (22°C and 5°C).

2.6.2 Scorecard sheet: The assessment of cashew nut apple juice samples was based on colour, flavor, odor, decanting and overall assessment. It has been realized using a linear hedonic scale. This nine-point scale, was ranged from “extremely poor” (points 1) to “extremely good” (points 9) [28-29]. As far as the color was concerned, the range varied from “extremely discolored” to “extremely colored”. And this was done for yellow apple juice. From “extremely less red” to “extremely red”, the action was performed for red apple juice. For the taste’s turn, the range was from “extremely bitter” to “extremely sweet”. Now, concerning the odor, the range varied from “extremely unpleasant” to “extremely pleasant”. For the settling, the range varied from “extremely unpleasant” to “extremely pleasant”. Finally, concerning the overall assessment, Things were done from “extremely unpleasant” to “extremely pleasant”. 2.6.3 Preparation and presentation of juice samples: The samples packaged in glass bottles, were pasteurized and then stored. The evaluation tests were conducted in a ventilated room, free of odors and other disruptions that could affect the panel's perception. Acceptability tests were conducted under white light. The samples were separately served, one by one to each taster using transparent glasses and seeking anonymity. A scoring sheet was given to each taster in order to increase their acceptance level.

2.7 Statistical analysis

The data generated by this study was statistically processed with the SPSS 11.19 statistical software. The significance of the parameters resulting from the characterization was assessed by the Duncun test at 5% threshold. Firstly, the analysis of the variance (ANOVA) allowed us to process data from the evaluation of biochemical and hematological parameters and secondly, data from the sensory analysis of cashew apple juice. Although a major difference (α<0.05) is revealed, the ANOVA test is supplemented by Turkey’s post ANOVA test to identify the variable(s) with very significant differences from the control values.

3. Results

3.1 pH variation

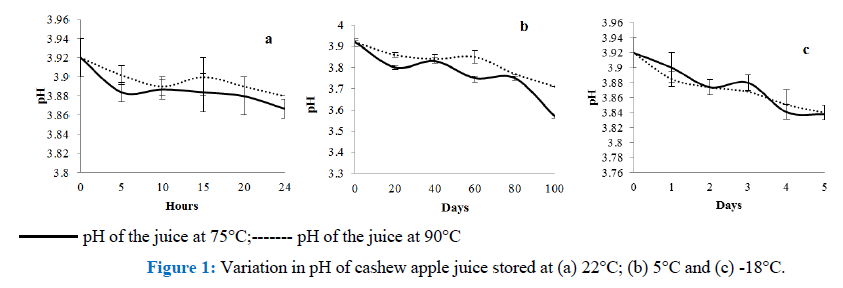

The stability study of cashew apple juice is focused on yellow apple juice from Bondoukou. The pH evolution of cashew apple juice samples varies according to the pasteurization scale (75°C/5 min and 90°C/30 s), the storage temperature and the storage time (Figure 1). The samples were stored for 24 hours, 5 days and 100 days respectively. In general, this evolution is marked by a decrease in pH under the three storage conditions. In juice samples, pasteurized and stored at 22°C ± 1°C, the pH increased from 3.92 to 3.87 for samples pasteurized at 75°C and from 3.92 to 3.88 for samples pasteurized at 90°C. For cashew apple juice samples stored at 5°C ± 1°C, the pH increased from 3.92 to 3.83 for pasteurized juice samples at 75°C and from 3.92 to 3.84 for pasteurized juice samples at 90°C. The pH evolution of juice samples stored at -18°C ± 1°C is similar to the other two storage conditions, which are marked by a decrease. Thus, the pH values increase from 3.92 to 3.57 for samples of pasteurized juice at 75°C and from 3.92 to 3.71. There is no significant difference (p<0.05) between the pH variations of the juice stored at different temperatures.

3.2 Variation in the ESR

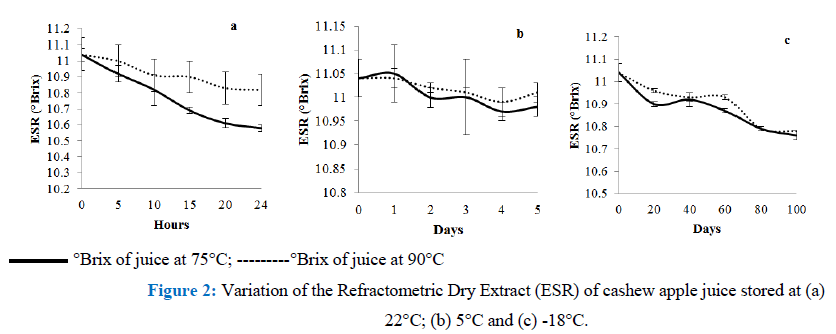

The evolution of the Refractometric Dry Extract (ESR) of juice samples stored at different temperatures (22°C ± 1°C; 5°C ± 1°C; -18°C ± 1°C) is marked by a decrease for all the samples (Figure 2). The variations in the ESR is 11.04 to 10.58°Brix and 11.04 to 10.82°Brix respectively, for samples pasteurized at 75°C and those pasteurized at 90°C. At the storage temperature of 22°C, the decrease in ESR is rapid during the 24-hour storage period for samples pasteurized at 75°C. The values have thus increased from 11.04 to 10.58°Brix. This decrease is less rapid for samples pasteurized at 90°C. In samples stored at 5°C, the evolution is always marked by a decrease in ESR but less marked compared to the first case. This evolution is done in 3 phases, including a phase of a slight increase in ESR in samples pasteurized at both scales. Then, comes a phase of decline, punctuated by oscillation and followed by a final recovery phase for the ESR. Thus, in samples pasteurized at 75°C, the ESR values varied from 11.04 to 10.98°Brix with a peak decrease at 10.97°Brix.

For those pasteurized at 90°C, the values are between 11.04 and 11.01°Brix with a peak decrease to 10.99°Brix. The various variations recorded are not statistically significant (p<0.05). However, the decrease in the ESR of samples pasteurized at 75°C is more marked than that of samples pasteurized at 90°C. For juice samples stored at -18°C, the evolution is similar to the 2 other storage conditions, i.e. a decrease in ESR. Thus, in samples pasteurized at 75°C, the ESR values varied from 11.04 to 10.76°Brix and for those pasteurized at 90°C, the values varied from 11.04 to 10.78°Brix. This decrease is punctuated by oscillation with peaks of 10.92°Brix and 10.93°Brix respectively, for samples pasteurized at 75°C and those pasteurized at 90°C. These variations are not statistically significant (p<0.05) for the different samples stored at -18°C. As with samples stored at 5°C and 22°C, the decrease in ESR of samples pasteurized at 75°C is faster than the decrease in ESR of samples stored at 90°C.

3.3 Variation of titratable acidity

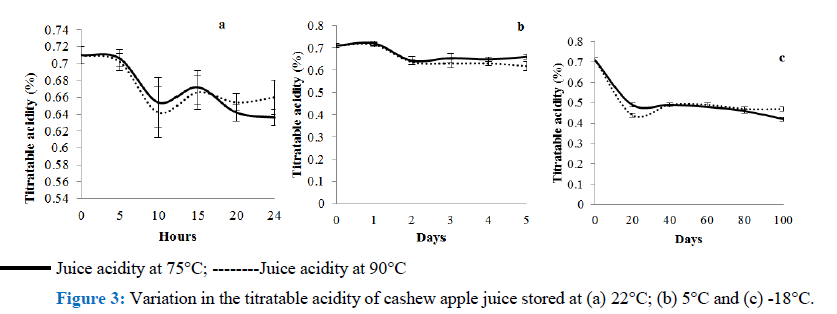

The Titratable acidity of the various pasteurized juice samples stored at the temperatures of this study decreases over time (Figure 3). It varies from 0.71 to 0.64% and from 0.71 to 0.66% respectively for samples pasteurized at 75°C and 90°C and stored at 22°C. This decrease is marked by 4 phases for samples pasteurized at 2 scales. We have a first phase where the acidity is stationary (therefore does not change) between 0 and 5 hours of storage, followed by a phase of decrease where the acidity increased to 0.65 and 0.64% respectively for samples pasteurized at 75°C and 90°C after 10 hours. This phase of decrease is followed by a titratable acid peak (0.67% and 0.66%, respectively) at 15 h of storage of the samples. The last phase is about a decrease of 0.64% and 0.66% with a more significant decrease for samples pasteurized at 75°C.

In samples stored at 5°C, the titratable acidity decreases, but with a stabilization level. Here, the titratable acidity varies from 0.71 to 0.66% and from 0.71 to 0.62% respectively for the two types of samples pasteurized at 75°C and 90°C. The evolution of acidity at this level is marked by 3 phases. The first is punctuated by a slight increase between 0 and 1 day, then a decrease after 2 days of storage. During these two phases, the evolution of the two samples is almost identical. From the second day onwards, acidity stabilizes with a slight increase for samples pasteurized at 75°C and a slight decrease for samples pasteurized at 90°C. Finally, the evolution of the titratable acidity of samples stored at -18°C is similar to other storage temperatures marked by a decrease during the storage period. Acidity decreases from 0.71 to 0.42% and from 0.71 to 0.47% respectively for juice samples pasteurized at 75°C and 90°C. The variation in titratable acidity is statistically not the same in (p<0.05) for the different samples. This decrease is marked by 2 phases, including a first phase of rapid decrease up to 20 days of storage, followed by a phase of a slight increase in acidity, which stabilizes from 40 days. This stabilization ends with a further decrease to 80 days for samples pasteurized at 75°C, and then reached a titratable acidity of 0.62%.

3.4 Variation in total and reducing sugar

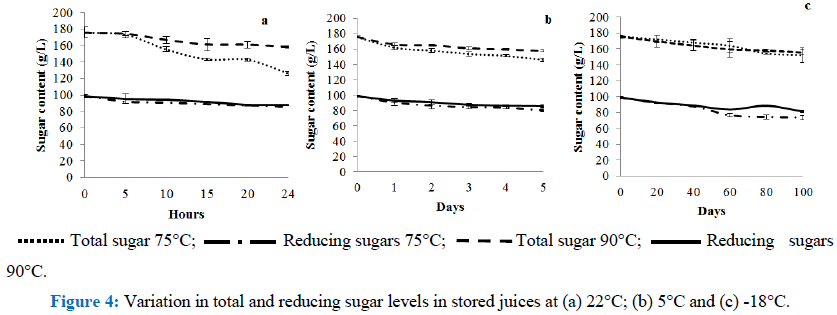

The evolution of total and reducing sugar is similar to the other parameters, i.e. marked by a decrease in these compounds in cashew apple juice samples (Figure 4). Among the three storage conditions, only samples stored at 22°C and -18°C have their sugar concentrations significantly reduced. This decrease is more pronounced for samples pasteurized at 75°C and stored at 22°C. At these storage temperatures, the total sugar of the samples pasteurized at 75°C range from 175.8 to 126.2 g/L and from 178.8 to 146 g/L respectively for the storage temperatures of 22°C and 5°C. Those of samples pasteurized at 90°C range from 175.8 to 158.5 g/L and from 175.8 to 157.2 g/L for storage temperatures of 22°C and 5°C respectively. In terms of reducing sugars, samples stored at -18°C show more decrease than other samples stored at 22°C and 5°C. This decrease shifts from 98.8 to 73.8 g/L and from 98.8 and 81.1 g/L respectively, for samples pasteurized at 75°C and 90°C. We can therefore attest that storage time has an impact on the reducing sugar and total sugar content of cashew apple juice samples.

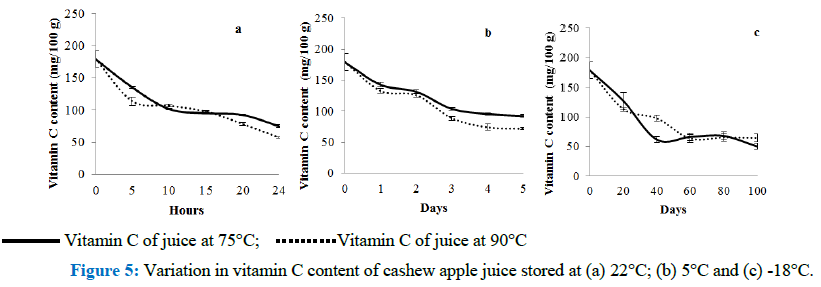

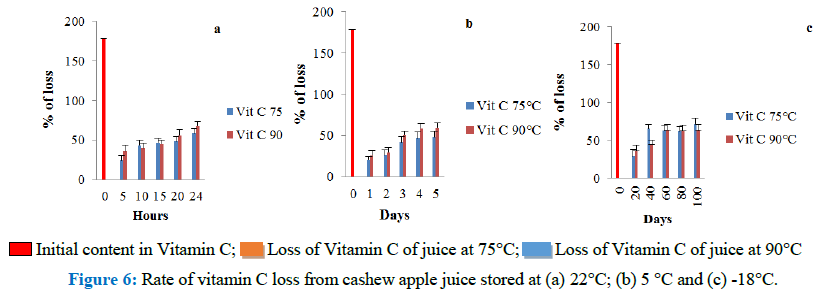

3.5 Variation de la Vitamine C et taux de perte en vitamine C

Among all the stability parameters in this study, vitamin C is by far the most unstable parameter. All storage conditions saw a drastic decrease in the vitamin C content of the samples (Figure 5). Thus, the vitamin C content decreased from 178.7 to 74.6 mg/100 g and from 178.7 to 57.3 mg/100 g, respectively, for samples pasteurized at 75°C and 90°C and stored at 22°C after 24 hours. For samples stored at 5°C, vitamin C decreased from 178.7 to 92.3 mg/100 g and from 178.7 to 71.9 respectively, for samples pasteurized at 75°C and 90°C after 5 days. Finally, for samples stored at -18°C, the decrease in vitamin C is 178.7 to 50.13 mg/100 g for samples pasteurized at 75°C and 178.7 to 64.6 mg/100 g for samples pasteurized at 90°C after 100 days of storage. These variations are statistically significant (p<0.05). The decrease in vitamin C content of samples appears to be greater in samples pasteurized at 90°C than in samples pasteurized at 75°C. In other words, the higher pasteurization temperature is high more vitamin C decreases. In addition, storage time also has an impact on vitamin C content, as samples stored for 100 days show the largest decreases. Vitamin C losses are summarized in Figure 6. These losses increase with the length of storage. For samples stored at 22°C, losses range from 24.45% to 58.25% and from 36.43% to 67.94% respectively for samples pasteurized at 75°C and 90°C. Samples stored at 5°C have losses of 20.31 to 48.35% and 25.85 to 59.76% for samples pasteurized at 75°C and 90°C respectively. Finally, for samples stored at -18°C, losses are in the range of 28.92 to 71.95% and 36.7 to 63.85% respectively for samples pasteurized at 75°C and 90°C.

3.6 Microbiological results

The microbiological count of cashew apple juice samples is summarized from Table 3 to 5. The three tables show an absence of total coliforms in the juice samples, which reflect the effectiveness of the heat treatments. However, the count revealed the presence of aerobic mesophilic germs (AMG), with proportions below the standard (<102 CFU). The analysis of the various tables shows that the number of GAMs is higher in juice samples stored at 22°C.

|

Hours |

Scales |

Germs |

|||

|

Total Coliforms |

Thermo tolerant coliforms |

Mesophilic Aerobics |

|||

|

Results |

Standard |

||||

|

5 |

75°C/5 mn |

Absence |

Absence |

13 |

<102UFC |

|

90°C/30 s |

Absence |

Absence |

03 |

<102UFC |

|

|

10 |

75°C/5 mn |

Absence |

Absence |

33 |

<102UFC |

|

90°C/30 s |

Absence |

Absence |

09 |

<102UFC |

|

|

15 |

75°C/5 mn |

Absence |

Absence |

59 |

<102UFC |

|

90°C/30 s |

Absence |

Absence |

14 |

<102UFC |

|

|

20 |

75°C/5 mn |

Absence |

Absence |

16 |

<102UFC |

|

90°C/30 s |

Absence |

Absence |

31 |

<102UFC |

|

|

24 |

75°C/5 mn |

Absence |

Absence |

22 |

<102UFC |

|

90°C/30 s |

Absence |

Absence |

54 |

<102UFC |

|

UFC-Colony Forming Unit

Table 3: Microbiological contents of juice samples stored at 22°C.

|

Days |

Scales |

Germs |

|||

|

Total Coliforms |

Thermo tolerant coliforms |

Mesophilic Aerobics |

|||

|

Results |

Standard |

||||

|

1 |

75°C/5 mn |

Absence |

Absence |

05 |

<102UFC |

|

90°C/30 s |

Absence |

Absence |

03 |

<102UFC |

|

|

2 |

75°C/5 mn |

Absence |

Absence |

15 |

<102UFC |

|

90°C/30 s |

Absence |

Absence |

07 |

<102UFC |

|

|

3 |

75°C/5 mn |

Absence |

Absence |

26 |

<102UFC |

|

90°C/30 s |

Absence |

Absence |

11 |

<102UFC |

|

|

4 |

75°C/5 mn |

Absence |

Absence |

33 |

<102UFC |

|

90°C/30 s |

Absence |

Absence |

08 |

<102UFC |

|

|

5 |

75°C/5 mn |

Absence |

Absence |

22 |

<102UFC |

|

90°C/30 s |

Absence |

Absence |

14 |

<102UFC |

|

UFC-Colony Forming Unit

Table 4: Microbiological contents of juice samples stored at 5°C.

|

Days |

Scales |

Germs |

|||

|

Total Coliforms |

Thermo tolerant coliforms |

Mesophilic Aerobics |

|||

|

Results |

Standard |

||||

|

20 |

75°C/5 mn |

Absence |

Absence |

03 |

<102UFC |

|

90°C/30 s |

Absence |

Absence |

01 |

<102UFC |

|

|

40 |

75°C/5 mn |

Absence |

Absence |

02 |

<102UFC |

|

90°C/30 s |

Absence |

Absence |

02 |

<102UFC |

|

|

60 |

75°C/5 mn |

Absence |

Absence |

05 |

<102UFC |

|

90°C/30 s |

Absence |

Absence |

02 |

<102UFC |

|

|

80 |

75°C/5 mn |

Absence |

Absence |

03 |

<102UFC |

|

90°C/30 s |

Absence |

Absence |

04 |

<102UFC |

|

|

100 |

75°C/5 mn |

Absence |

Absence |

02 |

<102UFC |

|

90°C/30 s |

Absence |

Absence |

02 |

<102UFC |

|

UFC-Colony Forming Unit

Table 5: Microbiological contents of juice samples stored at -18°C.

3.7 Organoleptic characteristics of cashew apple juice

The average sensory evaluation scores for yellow and red cashew apple juice are summarized from Table 6 to 9. Each table is a fusion of the averages of the scores obtained by the samples of yellow and red apple juice at each pasteurization scale. Thus, 5 attributes were submitted for evaluation to a panel of 30 people. These are colour, odour, taste, decantation and overall assessment. In terms of colour, the scores obtained vary from 6.1 to 6.7 for pasteurized juices at different scales and storage times. The odour scores range from 5.6 to 6.7. As for taste, the scores vary between 6 and 6.8. Finally, the settling and the overall assessment have scores ranging from 5.2 to 6.2 and 5.8 to 6.7 respectively. The scores are not statistically different (α<0.05) between samples at different storage times and between samples and controls of stored samples. The heat treatment and the different storage times did not affect the attributes of the juice samples according to the scores obtained. In addition, the different scores show that the tasters' judgments are at the level of the rating scale: “...rather (quite) pleasant”. Despite its unfavourable organoleptic character, the decanting of cashew apple juice was favourably received by the tasters. This positive response is demonstrated by scores ranging from 5.2 to 6.2. The cashew apple juice in this study is moderately appreciated according to the presented scale.

|

Attributes |

Fresh juice |

Juice pasteurized at 75°C/5 min |

||||

|

Storage time (H) |

||||||

|

5 |

10 |

15 |

20 |

24 |

||

|

Color |

6.6 ± 1.10a |

6.3 ± 1.01a |

6.3 ± 1.01a |

6.3 ± 1.22a |

6.5 ± 0.87a |

6.4 ± 1.32a |

|

Odour |

6.4 ± 1.20a |

6.2 ± 0.93a |

5.9 ± 1.20a |

6.1 ± 1.36a |

6.1 ± 1.01a |

6 ± 1.01a |

|

Taste |

6.5 ± 0.88a |

6.2 ± 0.83a |

6.7 ± 0.83a |

6.6 ± 0.97a |

6.6 ± 1.0a |

6.5 ± 0.87a |

|

Decantation |

5.8 ± 1.92a |

5.5 ± 1.62a |

6.4 ± 1.60a |

6.2 ± 1.67a |

6.2 ± 1.33a |

6.1 ± 1.47a |

|

Overall assessment |

6.6 ± 0.87a |

6.2 ± 0.87a |

6.2 ± 0.93a |

6.4 ± 1.20a |

6.3 ± 0.78a |

6.3 ± 0.92a |

The results are the average of 30 tastings. The averages affected by the same letter on the same line are not significantly different at the α<0.05 threshold according to the Tukey test.

Table 6: Average scores for cashew apple juice pasteurized at 75°C and stored at 22°C for 24 hours.

|

Attributes |

Fresh juice |

Juice pasteurized at 90 °C/30s |

||||

|

Storage time (H) |

||||||

|

5 |

10 |

15 |

20 |

24 |

||

|

Color |

6.7 ± 0.71a |

6.5 ± 0.83a |

6.4 ± 1.22a |

6.3 ± 1.20a |

6.3 ± 1.39a |

6.4 ± 1.13a |

|

Odour |

6.5 ± 0.86a |

6.7 ± 0.66a |

6.4 ± 1.0a |

6.4 ± 0.93a |

6.2 ± 1.14a |

6.3 ± 0.71a |

|

Taste |

6.4 ± 0.88a |

6.4 ± 0.88a |

6.6 ± 0.71a |

6.8 ± 0.83a |

6.8 ± 1.10a |

6.8 ± 0.53a |

|

Decantation |

6 ± 1.48a |

5.6 ± 1.50a |

5.5 ± 0.66a |

5.7 ± 1.74a |

5.7 ± 1.24a |

5.8 ± 1.32a |

|

Overall assessment |

6.7 ± 0.66a |

6 ± 0.50a |

6.3 ± 1.50a |

6.4 ± 0.78a |

6.1 ± 0.93a |

6.3 ± 0.53a |

The results are the average of 30 tastings. The averages affected by the same letter on the same line are not significantly different at the α<0.05 threshold according to the Tukey test.

Table 7: Average scores for cashew apple juice pasteurized at 90°C and stored at 22°C for 24 hours.

|

Attributes |

Fresh juice |

Juice pasteurized at 75 °C/5 min |

||||

|

Storage time (J) |

||||||

|

1 |

2 |

3 |

5 |

7 |

||

|

Color |

6.1 ± 1.13a |

6.2 ± 1.01a |

6.4 ± 1.0a |

6.4 ± 1.10a |

6.2 ± 0.87a |

6.2 ± 1.06a |

|

Odour |

6.2 ± 1.01a |

6.3 ± 0.88a |

6.5 ± 1.20a |

6.4 ± 1.20a |

6.6 ± 0.53a |

6.4 ± 0.91a |

|

Taste |

6.6 ± 0.78a |

6 ± 0.83a |

6.7 ± 1.0a |

6.6 ± 1.13a |

6.6 ± 0.83a |

6.3 ± 0.74a |

|

Decantation |

5.5 ± 1.58a |

6.4 ± 1.56a |

6.6 ± 1.87a |

6.4 ± 1.35a |

6.4 ± 1.75a |

6.5 ± 1.85a |

|

Overall assessment |

6.5 ± 0.71a |

6 ± 0.88a |

6.2 ± 1.17a |

5.9 ± 1.93a |

6.2 ± 0.53a |

6.0 ± 0.52a |

The results are the average of 30 tastings. The averages affected by the same letter on the same line are not significantly different at the α<0.05 threshold according to the Tukey test.

Table 8: Average scores for apple juice pasteurized at 75°C and stored at 5°C for 7 days.

|

Attributes |

Fresh juice |

Juice pasteurized at 90 °C/30 s |

||||

|

Storage time (J) |

||||||

|

1 |

2 |

3 |

5 |

7 |

||

|

Color |

6.1 ± 1.39a |

6.5 ± 0.92a |

6.3 ± 1.63a |

6.2 ± 1.47a |

6.2 ± 1.48a |

6.3 ± 1.33a |

|

Odour |

6.2 ± 0.83a |

5.6 ± 0.92a |

6 ± 1.37a |

6.2 ± 1.29a |

6.1 ± 0.98a |

6 ± 1.20a |

|

Taste |

6.6 ± 0.93a |

6.3 ± 0.71a |

6.6 ± 1.06a |

6.6 ± 1.26a |

6.8 ± 1.56a |

6.7 ± 0.88a |

|

Decantation |

5.5 ± 1.98a |

5.7 ± 1.81a |

5.2 ± 1.75a |

5.3 ± 1.43a |

5.6 ± 1.37a |

5.7 ± 1.22a |

|

Overall assessment |

6.5 ± 1.04a |

5.8 ± 0.71a |

6.2 ± 1.06a |

6 ± 1.16a |

6.1 ± 1.03a |

6.2 ± 1.42a |

The results are the average of 30 tastings. The averages affected by the same letter on the same line are not significantly different at the α<0.05 threshold according to the Tukey test.

Table 9: Average scores for apple juice pasteurized at 90°C and stored at 5°C for 7 days.

4. Discussion

In this study concerning stability, the impact of heat treatment (pasteurization) and storage conditions was evaluated on 6 parameters that could influence the qualitative and nutritional evolution of cashew apple juice. The yellow apple juice samples from Bondoukou were used in view of their lower content in vitamin C. Thus, pH, acidity, ESR, total and reducing sugars and vitamin C were monitored over time at laboratory temperature (22°C), refrigerated (5°C) and frozen (-18°C). Similarly, germs such as total coliforms, thermo-tolerant coliforms and mesophilic aerobic germs have been quantified in juices under the same conditions. These germs are markers of juice health and stability. Among the parameters studied, pH, ESR and acidity are indicators of the evolution of the environment while vitamin C, total and reducing sugars are degradable compounds whose contents or degradation products influence the environment. Among them, vitamin C is the compound whose degradation is the most rapid in this study. Retention in Vitamin C is often used as an estimate for the overall maintenance of nutrients in food products, as it is by far the least stable nutrient [30]. It is highly sensitive to oxidation and leaching into water-soluble matrices during storage [31]. Vitamin C begins to degrade immediately after harvest and regularly degrades during prolonged storage [32]. It also continues to deteriorate during prolonged storage of frozen products [33]. Among compounds showing antioxidant activity in orange juice, vitamin C is the most important. The contribution is 65-90% of all antioxidant activity in this juice [34]. However, cashew apple juice is 10 times richer in vitamin C than orange juice [11].

In this study, the parameters that may affect the degradation of the compounds studied (sugars and vitamin C) are the pasteurization rate, temperature and storage time. Pasteurized samples show a loss in vitamin C ranked between 20.31% and 36.7% just after the pasteurization. In addition, the initial losses of juice samples pasteurized at 90°C (36.43%; 25.85% and 36.7%) and stored under the 3 study conditions (22°C; 5°C and 18°C) are higher than those of samples pasteurized at 75°C. According to Blasco et al. [35], there are two different ways of degrading ascorbic acid that are observed during the heat treatment process: aerobic degradation followed by anaerobic degradation. At the beginning of the heating process, oxygen remains in abundance in the bottle and thus causes aerobic degradation of ascorbic acid. As the heating continues the atmosphere in the bottle becomes saturated with steam, so that the concentration in oxygen is minimal and the ascorbic acid is degraded under anaerobic conditions. The rapid decrease in vitamin C at the beginning of storage is attributed to the immediate reaction with dissolved oxygen [36]. The switch to anaerobic degradation mode results in a relative decrease, as shown by the different levels observed in the evolution curves of the preserved samples. However, the decrease continued during the storage period and the samples stored for 100 days saw their values decreasing more and more than the other samples. In general, samples pasteurized at 90°C have lost more vitamin C than samples pasteurized at 75°C during the storage.

According to Burdurly et al. [37], the degradation of ascorbic acid by aerobic and anaerobic routes depends on many factors such as oxygen, heat, light, storage temperature and storage time. Oxidation of vitamin C occurs mainly during heat treatment, while anaerobic degradation of vitamin C occurs mainly during storage. This is particularly observed in thermally preserved juices [35]. Oxygen is the most destructive ingredient in juice because it causes vitamin C degradation [38]. However, one of the main sugars in orange juice, fructose, can also cause vitamin C degradation. More the fructose content is high, more significant is the loss of vitamin C. On the other hand, a higher level of citric acid and malic acid will stabilize vitamin C [39]. Vitamin C has an obvious similarity with structural hexoses. Therefore, it is conceivable that the molecule could be used as a carbon source for respiration or bacterial growth and could be fermented [40]. The heat treatment of orange juice has shown that temperature has a strong influence and degradation is more important and rapid at high temperatures [41]. The low storage temperature did not prevent the degradation of vitamin C due to the storage time (100 days), leading to losses of vitamin C at 71.95% and 63.85%. The rapid drop in vitamin C levels in juice samples stored at 22°C also shows that the storage temperature is an important factor in the degradation process. In all cases, the thermolability of this compound is verified. Several authors have undertaken stability studies on cashew apple juice. For example, Costa et al. [42] in their stability study of cashew apple juice, they showed vitamin C losses ranging from 25.65 to 26.74% after a period of 12 months of storage. These losses are lower than those of this study because the treatment recommended by these authors was a microfiltration followed by a deaeration operation of the juice samples. The reduction in the amount of oxygen coupled with the treatment mode limited vitamin C losses.

Nair et al. [43] observed losses in the range of 29-59% still in cashew apple juice after 32 weeks of storage. However, despite the losses in this study, the levels of retention in vitamin C preserved juices show that heat treatments and cold storage are preservation pathways. Indeed, at the end of the different storage times, the samples stored at 22°C still had 74.6 mg / 100 g and 57.3 mg /100g of vitamin C. Those stored at 5°C had retentions between 92.3 mg / 100 g and 71.9 mg /100g and finally the samples stored at -18°C had retention levels of 50.13 mg / 100g to 64.6 mg /100g. It is true that the intake of vitamin C prescribed in different parts of the world is not uniform. For example, vitamin C intake prescribed in Great Britain is 30mg/day, while in the United States it is 60mg/day and 100mg/day in Japan. These variations show that Recommended Daily Intakes (RDI) of vitamin C should be higher than the amount required to prevent the onset of disease. Vitamin C has considerable functions that increase its role in the health status of the human body [44]. With regard to these RDIs in the different countries, retention in vitamin C, at the end of the different storage periods, is within acceptable ranges. In other words, the treatment mode (pasteurization) and cold storage give acceptable levels of retention for the daily supply of vitamin C despite the losses recorded. In both orange juice and cashew apple juice, ascorbic acid is the most important antioxidant [34].

Sugars are among the compounds that are degraded. In this study, total and reducing sugars were degraded during storage. The evolution of total and reducing sugars at all storage temperatures shows a decrease in these metabolites. Indeed, sugars under ideal conditions are the substrates metabolized by microorganisms to produce various compounds such as alcohols and acids. Among the different storage conditions, only those of samples stored at 22°C and -18°C showed significant variations in total and reducing sugars. At 22°C, the temperature seems to be the ideal factor for degradation, while at -18°C, storage time has increased oxidation phenomena induced by the anaerobic activities of chemical compounds. According to Corrêa and Faria [45], packaging materials, the nature of the treatment and storage conditions are the cause of the microbiological, enzymatic, chemical and physical alteration that causes sensory and nutritional damage. The decrease in sugars could also be explained by physical accidents during low temperature storage in juices [46]. Indeed, these authors showed by microscopy and differential thermal analysis of frozen fruit juice, the observation of glass transition of interstitial water (between the interstices of ice crystals). This transition caused the mobility of the solution and the collapse of the molecular structure of the oses (sucrose, fructose and glucose). More the storage time lasts; more frequent are these accidents, and less likely they are to reduce the content of the sugars concerned. At the microbiological level, there is the absence of coliforms (total and thermo-tolerant) and the presence of mesophilic aerobic germs (GAM) below the standard. These findings could be attributed to the pasteurization. The absence of coliforms and the current content of mesophilic aerobic germs are in accordance with Order No. 250 MSP/DSPH of 18 November 1988 setting microbiological standards for fruit juices. Observation of the mobility of mesophilic aerobic germs, their filamentous shape and the whitish colour of the colonies could reinforce the presumption of fungi, especially yeasts. In addition, these results show the effectiveness of the two pasteurization scales. Heat treatments and aseptic methods are efficient methods for maintaining the physicochemical characteristics of juices [47]. They can preserve these characteristics until 12 months [42]. However, despite the effectiveness of the scales in this study, the environment remained the site of metabolic activities due to enzymatic and chemical but also microbiological reactions for samples stored at 22°C. Chemical and microbiological monitoring of juice samples showed that there was a general decrease in pH, total and reducing sugars, ESR and titratable acidity. This state of the environment is due to the deterioration of the cashew apple juice samples.

According to Ajibola et al. [39], there is a significant correlation between pH and vitamin C deterioration in fruit juices. The decrease in pH is synonymous with an acidification of the environment and this is due to the degradation products of the substrates. The rapid decrease in the pH of pasteurized juice samples shows the effectiveness of the 90°C/30 s scale compared to the 75°C/30 mn scale. The acidification of the environment also influences the ESR, giving to it an idea of the sugar contained in the environment. All these things are supported by the decrease in the rate of total and reducing sugars. As the pH decreases, the titratable acidity also decreases. The term “titratable acidity” is often incorrectly identified with the term “total acidity”. Titratable acidity is made of acids that can be titrated by strong base solutions and that have their free carboxylic (COOH) functions [48]. Here, the acidity we are talking about is related to the malic acid content. On the other hand, pH measures total acidity, i.e. the sum of all the organic acids in the medium. Whether pH, acidity or ESR, samples stored at 22°C decrease more rapidly than those stored at 5°C and 18°C. On the other hand, samples pasteurized at 75°C generally have a faster drop in these parameters than samples pasteurized at 90°C. The cold, therefore seems to influence these evolutions as well as the pasteurization scale. The rapid decrease in these parameters (pH, titratable acidity, ESR) at the beginning of storage is due to the presence of oxygen, which accelerates the degradation of compounds such as vitamin C [42]. Moreover, the decrease in pH also leads to a decrease in titratable acidity as observed by Das et al. [49]. Indeed, malic acid being an organic acid (therefore a weak acid), would not dissociate at low ph. However, in their undissociated form at acid pH, organic acids would be more effective on microorganisms. These reactions combined with the effect of the heat treatment better support the microbial safety of the stored juices. Despite the different physicochemical variations in the environment, the sensory evaluation of samples pasteurized at 75°C and 90°C and then stored hasn’t show any significant change. Because there was no significant variation between the controls (fresh juice) and the treated samples. Scores obtained for both controls and treated samples indicate an average acceptance of cashew apple juice. Talasila et al. [28] obtained higher scores (between 7.5 and 9) for the same attributes on cashew apple juice in India. These better results were due to the use of clarifying agents that reduced the tannin content of the juices. All things that would have favoured a better acceptance of these juices. Indeed, tannins and other polyphenols are incriminated to be the basis of the astringency of the juice. However, in this study, the only treatment undergone by the samples is heat treatment. Even if astringency has remained as such, cashew apple juice is considered in the range of “rather (quite) pleasant product”. This implies that cashew apple juice is a product that can be valued both for its nutritional richness and its organoleptic character.

5. Conclusion

The stability study of the different samples of pasteurized cashew apple juice at 75°C/5 mn and 90°C/30 s showed a variation in the different analyzed parameters. Pasteurization scales and storage time have shown a significant influence on the evolution of these parameters. The evolution of pH, acidity and ESR is due to the degradation of total sugars, reducing sugars and vitamin C used as substrates in the various reactions. Among these substrates studied, vitamin C is the compound that degrades most rapidly. The heat treatment reduced the proportions of mesophilic aerobic germs below the critical limits of the standards used for this study. In addition, associated with cold, degradation reactions were slowed down and juices were better stabilized and controlled. Thermal treatment, notwithstanding the degradation caused by compounds such as vitamin C, appears to be an effective means of preserving juices. The two pasteurization scales appear to be effective in terms of obtained results. But the pasteurization scale 75°C/5 min and the storage time for 5 days can be retained for a better preservation of the physicochemical characteristics.

Acknowledgments

The authors extend their sincere thanks to the “Laboratoire National de Santé Publique” (LNSP) located in Côte d'Ivoire for the availability of equipment and reagents.

Conflicts of Interest

No conflicts of interest.

References

- Michodjehoun ML, Souquet JM, Fulcrand H, et al. Monomeric phenols of cashew apple (Anacardium occidentale). Journal of Food Chemistry 112 (2009): 851-857.

- Dedehou ESCA, Dossou J, Soumanou MM. Étude diagnostique des technologies de transformation de la pomme de cajou en jus au Bénin. International Journal of Biological and Chemical Sciences 9 (2015): 371-387.

- Philippe L, Steev L, Hubert S. Study for the preparation of a strategy for the development of the cashew nut sector in Côte d'Ivoire. Diagnostic Report (2012): 90.

- FAO statistical databases, Food and Agriculture Organization of the United Nations, Rome (2019).

- Queiroz C, Lopes MLM, Fialho E, et al. Changes in bioactive compounds and antioxidant capacity of fresh-cut cashew apple. Food Research International 44 (2011): 1459-1462.

- Lautié E, Domier M, Filho MDS, et al. Les produits de l’anacardier: Caractéristiques, voies de valorisation et marchés. Fruit 56 (2001): 235-248.

- Sivagurunathan P, Sivasankari S, 1muthukkaruppan SM. Characterisation of cashew apple (Anacardium occidentale) fruits collected from Ariyalur District. Journal of Biosciences Research 1 (2010): 101-107.

- Adou M, Kouassi DA, Tetchi FA, et al. Phenolic profile of Cashew (anacardium Ocidentale L.) of Yamoussoukro and Korhogo, Cote d'Ivoire. Journal of Applied Biosciences 49 (2012a): 333-338.

- Padonou SW, Olou D, Houssou P, et al. Comparaison de quelques techniques d’extraction pour l’amélioration de la production et de la qualité du jus de pommes d’anacarde. Journal of Applied Biosciences 96 (2015): 9063-9071.

- Yogone BJL, Manda P, Adou M, et al. Separate consumption of fresh cow milk and cashew apple juice effect on the rat. Journal of Chemical, Biological and Physical Sciences 8 (2018): 953-963.

- Akinwalé TO. Cashew apple juice: Its use in fortifying the nutritional quality of some tropical fruits. European Food Research and Technology 211 (2000): 205-207.

- Jihong W, Haiyan GB, Zhao LA, et al. Chemical compositional characterization of some apple cultivars. Food Chemistry 103 (2007): 88-93.

- Adou M, Tetchi FA, Gbané M, et al. Physicochemical characterization of cashew apple juice (Anacardium Occidentale, L.) from Yamoussoukro (Cote d’Ivoire). Innovative Romanian Food Biotechnology 11 (2012b): 32-43.

- Morton JF. Cashew Apple. In: Fruits of warm climates. Julia F Morton, Miami, Florida, USA (1987): 239-240.

- Shen YC, Chen SL, Zhuang SR, et al. Contribution of tomato phenolics to suppression of COX-2 expression in KB cells. Journal of Food Science 73 (2008): 1-10.

- Yang J, Liu RH, Halim L. Antioxidant and antiproliferative activities of common edible nut seeds. LWT-Food Science and Technology 42 (2009): 1-8.

- Lacroix E. Les anacardiers, les noix cajou et la filière anacarde à bassilia et au Bénin. Térra Systems 1 (2003): 1-47.

- Houssou P, Montcho M, Godjo T, et al. Diagnostic sur les technologies de transformation de la pomme et de la noix cajou au Bénin. Rapport d’étude, PTAA (2004): 26.

- Soro D. Couplage de procédés membranaires pour la clarification et la concentration du jus de pomme de cajou: performances et impacts sur la qualité des produits. Thèse, Montpellier Supagro, France (2012): 156.

- Soro D, Moctar C, Kone YK, et al. Valorisation de la pomme de cajou (Anacardium occidentale) et impact de la concentration sous vide à différentes températures sur la qualité du jus. International Journal of Innovation and Applied Studies 19 (2017): 98-107.

- Soro D, Abreu F, Assidjo E, et al. The cashew (anacardium occidentale) industry in Côte d'Ivoire: analysis and prospects for development. Fruits 66 (2011): 237-245.

- Lowor ST, Agyente-Badu CK. Mineal and proximate composition of Cashew apple (Anacardium occidentale L.) juice from Northern Savannah, Forest and Costal Savannah region in Ghana. American Journal of Food Technology 4 (2009): 154-161.

- Adou M, Tetchi F, Gbane M, et al. Minerals Composition of the Cashew Apple Juice (Anacardium occidentale ) of Yamoussoukro, Cote d'Ivoire. Pakistan Journal of Nutrition 10 (2011): 1109-1114.

- Crisóstomo LA, Rossetti AG, Pimentel CRM, et al. Produtividade, atributos industriais e avaliação econômica de castanha em cajueiroanão precoce adubadocom doses crescentes de nitrogênio e potássioem cultivos obsequeiro. Revista Ciência Agronômica 35 (2004): 87-95.

- Diop AG, Sakho M, Dornier M, et al. Study of the baobab fruit and the transformation of the pulp into nectar. Regional Scientific and Pedagogical Seminar (GP3A) at the University of Ouagadougou (Burkina-Faso) (2005): 6.

- Official Methods of Analysis, (16th Edn.), Association of Official AnalyticalChemists, Arlington, VA (1995).

- Stone H, Sidel JL. The roles of sensory evaluation in the food industry. Food Quality and Preference 23 (1992): 65-73.

- Talasila U, Vechalapua RR, Khasim BS. Preservation and shelf life extension of cashew apple juice. Internet Journal of Food Safety 13 (2011): 275-280.

- General guidelines for performing hedonic tests in a sensory or indoor sensory evaluation laboratory involving consumers. Compendium of standards 6 (2000): 1-60.

- Erentuk S, Gualaboglu MS, Gultekin S. The effects of cutting and drying medium on the vitamin C content of rosehip during drying. Journal of Food Engineering 68 (2005): 513-518.

- Franke AA, Custer LJ, Arakaki C, et al. Vitamin C and flavonoid levels of fruits and vegetables consumed in Hawaii. Journal of Food Composition and Analysis 17 (2004): 1-35.

- Murcia MA, Opez-Ayerra BLA, Martinez-Toma M, et al. Industrial processing of broccoli in fruits. Journal of the Science of Food and Agriculture 80 (2000): 1882- 1886.

- Landl A, Abadias M, Sárraga C, et al. Effect of high pressure processing on the quality of acidified Granny Smith apple purée product. Innovative Food Science and Emerging Technologies 11 (2010): 557-564.

- Gardner PT, Tamsin AC, McPhail DB, et al. The relative contributions of vitamin C, carotenoids and phenolics to the antioxidant potential of fruit juices. Food Chemistry 68 (2000): 471-474.

- Blasco R, Esteve MJ, Frigola A, et al. Ascorbic acid degradation kinetics in mushrooms in a high-temperature short time process controlled by ather more sistometer. Lebensmmittel-Wissenschaft and Technologie 37 (2004): 171-175.

- Angeliki CP, Nikolaos GS, Petros ST. The effect of storage on the antioxidant activity of reconstituted orange juice which had been pasteurized by high pressure or heat. International Journal of Food Science and Technology 39 (2004): 783-791.

- Burdurly HS, Koca N, Karadeniz F. Degradation of vitamin C in citrus juice concentrates during storage. Journal of Food Engineering 74 (2006): 211-216.

- Zerdin K, Michael LR, Vermue J. The vitamin C content of orange juice packed in an oxygen scaven germaterial. Food Chemistry 82 (2003): 387-395.

- Ajibola VO, Babatunde OA, Suleiman S. The effect of storage method on the vitamin C content in some tropical fruit juices. Trends Applied Sciences Research 4 (2009): 79-84.

- Eddy BP, Ingram M. Interactions between ascorbic acid and bacteria. HTM Bacteriological Reviews provided courtesy American Microbiology (ASM). Bacteriological Reviews 17 (1953): 93-107.

- Vikram VB, Ramesh MN, Prapulla SG. Thermal degradation kinetics of nutrients in orange juice by electromagnetic and conventional methods. Journal of Food Engineering 69 (2005): 31-40.

- Costa MCO, Maia GA, Figueiredo RW, et al. Storage stability of cashew apple juice preserved by hot fill and aseptic processes. Ciência e Tecnologiade Alimentos 23 (2003): 106-109.

- Nair MK, Rao EVVB, Nambiar KKN. Cashew (Anacardium occidentale ) Kerala: Central Plantation Crops Research Institut (1979): 169.

- Walingo MK. Role of vitamin C (ascorbic acid) on human health, are view. African Journal of Food Agriculture and Nutritional Development 5 (2005): 1-13.

- Corrêa Neto RS Faria JAF. Factors that influence the quality of orange juice. Food Science and Technology 19 (1999): 153-160.

- Slade L, Levine H. Cryostabilization Technology: Thermoanalytical evaluation of food ingredients and systems. Critical Reviews in Food Science and Nutrition 21 (1990): 115360.

- Machado De Souza PH, Maia GA. Chemical, physico-chemical and microbiological evaluation of single strenght fruit juices: pineapple, cashew apple and passion. Ciência e Tecnologiade Alimentos 26 (2006): 98-103.

- Rajkovic MB, Novakovic ID, Petrovic A. Determination of titratable acidity in white wine. Journal of Agricultural Sciences 52 (2007): 169-184.

- Das DK, Dutta H, Mahanta CL. Development of a rice starch-based coating with antioxidant and microbe-barrier properties and study of its effect on tomatoes stored at room temperature. LWT-Food Science and Technology 50 (2013): 272-278.