Optimal Fermentation Conditions and Storage Period of Fermented Beverages Made from Demineralized Whey Using Kluyveromyces marxians

Article Information

Naoki Yamahata1, Yosuke Toyotake1, Satomi Kunieda2, Mamoru Wakayama1*

1Department of Biotechnology, College of Life Sciences, Ritsumeikan University, Shiga, Japan

2Department of Gastronomy Management, College of Gastronomy Management, Ritsumeikan University, Shiga, Japan

*Corresponding Author: Mamoru Wakayama, Ritsumeikan University, 1-1-1 Noji-higashi, Kusatsu, Shiga, 525-8577, Japan

Received: 08 January 2020; Accepted: 20 January 2020; Published: 31 January 2020

Citation: Naoki Yamahata, Yosuke Toyotake, Satomi Kunieda, Mamoru Wakayama. Optimal Fermentation Conditions and Storage Period of Fermented Beverages Made from Demineralized Whey Using Kluyveromyces marxians. Journal of Food Science and Nutrition Research 3 (2020): 001-017.

Share at FacebookAbstract

Fermented beverages made from demineralized whey (DMW) as a starting material have a higher sensory acceptability compared to those made from raw whey (RW). Here we investigated the optimal fermentation conditions, namely, temperature and initial pH, and storage period of fermented DMW-based beverages. The 20% w/v DMW solutions were fermented with pure cultured Kluyveromyces marxianus at various temperatures and initial pH values. Multiple sensory evaluations, such as an acceptance test, a descriptive test, and a preference ranking test, were conducted to determine the optimal initial pH and storage period. The final ethanol concentrations at selected fermentation temperatures were 9.6% v/v at 20°C, 9.6% at 25°C, 9.5% at 30°C, 5.8% at 35°C, and 3.6% at 40°C, and the fermentation rate was the highest at 30°C. No differences were observed in either fermentation or sensory characteristics at selected initial pH values (pH 7, pH 6, and pH 5). The optimal fermentation conditions were found to be a fermentation temperature of 30°C and an initial pH of pH 7. Although the preference for DMW-based beverages gradually decreased with storage, the storage period was assessed to extend to 4 weeks. These results indicate that approaches other than fermentation conditions, such as carbonation, aging, and serving temperature, should be used to improve the sensory preference of fermented whey-based beverages.

Keywords

Multiple sensory evaluations, Whey, Fermented beverages, Yeast, Kluyveromyces marxianus

Multiple sensory evaluations articles, Whey articles, Fermented beverages articles, Yeast articles, Kluyveromyces marxianus articles

Multiple sensory evaluations articles Multiple sensory evaluations Research articles Multiple sensory evaluations review articles Multiple sensory evaluations PubMed articles Multiple sensory evaluations PubMed Central articles Multiple sensory evaluations 2023 articles Multiple sensory evaluations 2024 articles Multiple sensory evaluations Scopus articles Multiple sensory evaluations impact factor journals Multiple sensory evaluations Scopus journals Multiple sensory evaluations PubMed journals Multiple sensory evaluations medical journals Multiple sensory evaluations free journals Multiple sensory evaluations best journals Multiple sensory evaluations top journals Multiple sensory evaluations free medical journals Multiple sensory evaluations famous journals Multiple sensory evaluations Google Scholar indexed journals Whey articles Whey Research articles Whey review articles Whey PubMed articles Whey PubMed Central articles Whey 2023 articles Whey 2024 articles Whey Scopus articles Whey impact factor journals Whey Scopus journals Whey PubMed journals Whey medical journals Whey free journals Whey best journals Whey top journals Whey free medical journals Whey famous journals Whey Google Scholar indexed journals Fermented beverages articles Fermented beverages Research articles Fermented beverages review articles Fermented beverages PubMed articles Fermented beverages PubMed Central articles Fermented beverages 2023 articles Fermented beverages 2024 articles Fermented beverages Scopus articles Fermented beverages impact factor journals Fermented beverages Scopus journals Fermented beverages PubMed journals Fermented beverages medical journals Fermented beverages free journals Fermented beverages best journals Fermented beverages top journals Fermented beverages free medical journals Fermented beverages famous journals Fermented beverages Google Scholar indexed journals Yeast articles Yeast Research articles Yeast review articles Yeast PubMed articles Yeast PubMed Central articles Yeast 2023 articles Yeast 2024 articles Yeast Scopus articles Yeast impact factor journals Yeast Scopus journals Yeast PubMed journals Yeast medical journals Yeast free journals Yeast best journals Yeast top journals Yeast free medical journals Yeast famous journals Yeast Google Scholar indexed journals Kluyveromyces marxianus articles Kluyveromyces marxianus Research articles Kluyveromyces marxianus review articles Kluyveromyces marxianus PubMed articles Kluyveromyces marxianus PubMed Central articles Kluyveromyces marxianus 2023 articles Kluyveromyces marxianus 2024 articles Kluyveromyces marxianus Scopus articles Kluyveromyces marxianus impact factor journals Kluyveromyces marxianus Scopus journals Kluyveromyces marxianus PubMed journals Kluyveromyces marxianus medical journals Kluyveromyces marxianus free journals Kluyveromyces marxianus best journals Kluyveromyces marxianus top journals Kluyveromyces marxianus free medical journals Kluyveromyces marxianus famous journals Kluyveromyces marxianus Google Scholar indexed journals livestock articles livestock Research articles livestock review articles livestock PubMed articles livestock PubMed Central articles livestock 2023 articles livestock 2024 articles livestock Scopus articles livestock impact factor journals livestock Scopus journals livestock PubMed journals livestock medical journals livestock free journals livestock best journals livestock top journals livestock free medical journals livestock famous journals livestock Google Scholar indexed journals beverages articles beverages Research articles beverages review articles beverages PubMed articles beverages PubMed Central articles beverages 2023 articles beverages 2024 articles beverages Scopus articles beverages impact factor journals beverages Scopus journals beverages PubMed journals beverages medical journals beverages free journals beverages best journals beverages top journals beverages free medical journals beverages famous journals beverages Google Scholar indexed journals US Food and Drug Administration articles US Food and Drug Administration Research articles US Food and Drug Administration review articles US Food and Drug Administration PubMed articles US Food and Drug Administration PubMed Central articles US Food and Drug Administration 2023 articles US Food and Drug Administration 2024 articles US Food and Drug Administration Scopus articles US Food and Drug Administration impact factor journals US Food and Drug Administration Scopus journals US Food and Drug Administration PubMed journals US Food and Drug Administration medical journals US Food and Drug Administration free journals US Food and Drug Administration best journals US Food and Drug Administration top journals US Food and Drug Administration free medical journals US Food and Drug Administration famous journals US Food and Drug Administration Google Scholar indexed journals biotechnological application articles biotechnological application Research articles biotechnological application review articles biotechnological application PubMed articles biotechnological application PubMed Central articles biotechnological application 2023 articles biotechnological application 2024 articles biotechnological application Scopus articles biotechnological application impact factor journals biotechnological application Scopus journals biotechnological application PubMed journals biotechnological application medical journals biotechnological application free journals biotechnological application best journals biotechnological application top journals biotechnological application free medical journals biotechnological application famous journals biotechnological application Google Scholar indexed journals

Article Details

1. Introduction

Whey is a yellow/green liquid that remains after milk casein has been coagulated and removed, and is known as a by-product of cheese manufacturing [1]. For every 1 kg of cheese production, about 9 kg of whey is generated [2]. The annual production of whey is estimated to be more than 200 million tons worldwide [3]. Approximately 60% of whey is industrially utilized, of which 58% is used as either edible lactose or dried whey powder, 35% is processed into whey protein concentrate and whey protein isolate, and the remaining 7% is processed into the so-called demineralized blends. The 40% of whey not industrially utilized is directly used for livestock feed or agricultural fertilizer, or is simply discarded [4]. Whey has been considered a major source of environmental pollution in the dairy industry due to its high biochemical oxygen demand (30,000-50,000 ppm) and chemical oxygen demand (60,000-80,000 ppm) [5]. In addition to these aspects of environmental pollution, the disposal of whey causes a loss of potential food and energy because whey retains 55% of milk nutrients [6].

Whey has been used as a functional substrate in food industry such as food additives, fermented foods, and beverages [7]. Whey protein is known to have low sensory acceptance due to its undesirable aftertaste, astringency, and aroma in beverages [1, 8, 9]. Many food researchers have developed whey-based beverages using particular approaches to address the challenge of low sensory acceptance of whey: fermented beverages using kefir grains [10, 11] or lactic acid bacteria [12, 13], mixtures of fruit [14-16], and distilled liquors [17]. Many of these developed beverages from whey are non-alcohol or low-alcohol beverages. However, there are few studies on high-alcohol beverages that are expected to have a commercial value such as fermented whey beverages brewed with pure cultured yeast are not extensively produced.

The lactose-fermenting yeast, Kluyveromyces marxianus, has been designated as GRAS (generally recognized as safe) by the US Food and Drug Administration, and is suitable for the development of fermented beverages. K. marxianus has been more widely adopted for industrial utilization compared to the predominant research species within the Kluyveromyces genus, Kluyveromyces lactis, due to its advantageous qualities in biotechnological application such as the ability to assimilate a wide variety of substrates, rapid growth rate, and thermotolerance [18, 19]. In addition, genetic modification of K. marxianus is unnecessary to produce high-alcohol beverages because it has high efficiency in producing ethanol from lactose. On the other hand, the typical brewer’s yeast, Saccharomyces cerevisiae, has no ability to assimilate lactose and thus requires approaches such as prehydrolysis of lactose, protoplast fusion, and genetic recombination [20].

Our previous study revealed that demineralized whey (DMW) was more acceptable than raw whey (RW) as a starting material to produce fermented whey beverages using K. marxianus. Although many efforts have been made to produce the whey-based beverages described in the preceding, these beverages are made from RW. Few studies have adopted DMW for the production of alcohol beverages [21]. Recent literature using DMW has focused on lactic acid beverages [22, 23]. The fermented beverages made from whey alone using pure cultured yeast are generally considered to have low acceptance; however, improvement is possible. This study aims to identify the optimal fermentation conditions, namely temperature and initial pH, and to assess the storage period of fermented beverages using multiple sensory evaluations, such as an acceptance test, a descriptive test, and a preference ranking test.

2. Materials And Methods

2.1 Microorganism

The lactose-fermenting yeast K. marxianus strain NBRC 1735 (NITE Biological Resource Center, Chiba, Japan) was used in this study. The yeast was precultured in 20 mL of liquid YPL medium containing 1.0% w/v yeast extract, 2.0% polypeptone, and 2.0% lactose within 100-mL Erlenmeyer flasks at 30°C for 24 h under agitation (160 rpm).

2.2 Media and fermentation conditions

Demineralized whey (DMW) powder (MEGMILK SNOW BRAND Co., Ltd., Hokkaido, Japan) was stored at 4°C. In our previous study, the fermented beverage made from initial DMW concentration of 20% w/v was preferred by the assessors over other initial concentrations of DMW of 10% w/v and 15% w/v [24]. The present study adopted 20% w/v DMW as the initial concentration for all experiments. DMW powder of 100 g was dissolved in 500 mL mineral water within 500-mL glass bottles sealed with Silicosen stoppers (Shin-Etsu Polymer Co., Ltd., Tokyo, Japan). The mineral water was sourced from Azumino, Nagano, Japan (potassium 0.4 mg/L, calcium 5.2 mg/L, magnesium 2.2 mg/L, water hardness 22 mg/L, and pH 7.4) by Japanese Consumers’ Cooperative Union. Well-stirred DMW solutions were pasteurized at 65°C for 30 min in a water bath and then rapidly cooled to the selected fermentation temperature. The pasteurized solutions were then inoculated with precultured yeast, were fermented under static conditions at 30°C except during the trial for optimal fermentation temperature, and were periodically sampled to measure the consumption of lactose and production of ethanol. After fermentation, the beverages were filtered and stored at 4°C until the sensory evaluation.

2.3 Compositional analyses

Before analyses, the samples were centrifuged at 12,000 rpm for 5 min at room temperature. The concentration of lactose was determined by the Nelson-Somogyi method [25, 26]. The concentration of ethanol was determined by gas chromatography with a flame ionization detector (GC-FID), using a Shimadzu GC-2025 system (SHIMADZU Co., Kyoto, Japan), Stabilwax capillary column (30 m, 0.25 mm i.d., 0.25 µm d.f.; Restek Co., Pennsylvania, USA) at a split ratio of 1:25, and helium as the carrier gas at 35 cm/s. The injector and FID were heated to 230°C. The column temperature program was as follows: 50°C for 5 min, then raised at 15°C/min to 200°C and held for 3 min. n-Amyl alcohol (0.01% v/v) was used as the internal standard and 1 µL samples were injected.

2.4 Fermentation of whey

2.4.1 Optimal fermentation temperature: To identify the best fermentation temperature, DMW solutions were fermented at selected temperatures: 20°C, 25°C, 30°C, 35°C, and 40°C. The optimal fermentation temperature was determined based on the fermentation rate.

2.4.2 Optimal initial pH: To determine the best initial pH for fermentation and sensory characteristics, we performed the fermentation of DMW solutions at selected initial pH values: pH 7, pH 6, pH 5, and pH 4. The original pH of the 20% w/v DMW solution was pH 7, and the pH was adjusted to appropriate values by adding food-grade lactic acid (90%) to the DMW solutions. The amount of lactic acid added was confirmed in preliminary experiments: 250 µL at pH 6, 675 µL at pH 5, and 1800 µL at pH 4. During fermentation, in addition to measuring lactose and ethanol concentrations, pH was also measured using LAQUAtwin pH meters (HORIBA, Ltd., Kyoto, Japan). We conducted the sensory evaluations on fermented DMW beverages with initial values of pH 7, pH 6, and pH 5, but not at pH 4, because the fermentation rate was extremely slow under the pH 4 condition and the fermentation was not complete at 16 days.

2.4.3 Storage period: The 20% w/v DMW solutions were fermented at 30°C until the lactose concentration was below 1% w/v and then were filtered and stored at 4°C for 0, 2, and 4 weeks. To simultaneously conduct the sensory evaluations, the start of the fermentation of DMW solutions for each storage period was accordingly adjusted.

2.5 Sensory evaluation

Multiple sensory evaluations were conducted with reference to the International Organization for Standardization (ISO) guidance [27]. The fermented beverages were evaluated by untrained assessors who were students at Ritsumeikan University. The number of assessors was 57 (39 men and 18 women, aged 20s) for the determination of optimal initial pH and 53 (32 men and 21 women, aged 20s) for the assessment of the storage period. For the acceptance test, assessors evaluated the overall acceptability first and then scored the acceptability of specific attributes using a 9-point hedonic scale [28]: 1, dislike extremely; 5, neither like nor dislike; and 9, like extremely. We conducted the descriptive test at the same time to confirm the correlation between the intensity of specific attributes and overall acceptability using a 9-point interval scale [29]: 1, extremely weak; 5, neutral; and 9, extremely strong. The specific attributes were sourness and astringency in the experiment to identify the optimal initial pH and sourness and bitterness to assess the effect of the length of storage. We also conducted a preference ranking test to determine whether the sensory preference changed with the initial pH of DMW solutions and whether the preference decreased with a longer storage period for fermented beverages. The assessors were asked not to give the same rank to different samples. In conducting the sensory evaluation, the samples were first cooled in an ice bath. Approximately 20 mL of each sample was served in a 60-mL clear plastic cup coded with a three-digit number, and samples were evaluated in a monadic and random order. The assessors were instructed to rinse their mouths with water before testing each sample.

2.6 Statistical analyses

All fermentation tests were performed in triplicate and the results were expressed as the mean ± SD. The results of the sensory evaluations were compared by non-parametric tests because the data were not always normally distributed. The experimental data from the sensory evaluation were submitted to the Friedman test and post hoc Wilcoxon signed-rank test with Bonferroni correction. Spearman’s rank correlation coefficient was used to measure the correlation between the intensity of specific attributes and overall acceptability. The results of preference ranking tests were graphically displayed using Baba’s method [30]. The null hypothesis for one item in the rank graph was H0: pl = 1/k (where pl represents the probabilities that one item is determined to be in the l rank and k represents the number of items), which means the item was randomly ranked. All analyses were conducted using Microsoft Excel 2016 and a statistical program (ystat2013, Igaku Tosho Press, Co. Ltd., Tokyo, Japan). Statistical significance for all tests was set at P < 0.05.

3. Results and Discussion

3.1 Optimal fermentation temperature

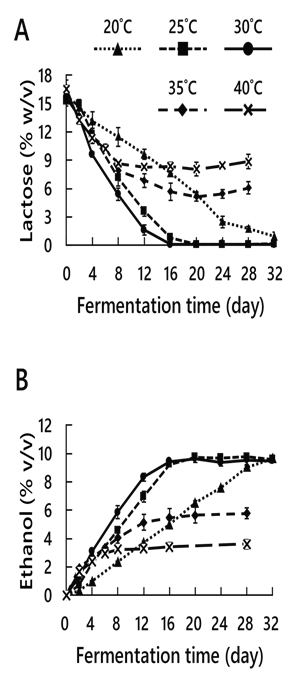

The best fermentation temperature of DMW solutions was 30°C decided from the fermentation rate (Figure 1). The final ethanol concentrations were 9.6% v/v at 20°C, 9.6% at 25°C, 9.5% at 30°C, 5.8% at 35°C, and 3.6% at 40°C. At the higher temperatures of 35°C and 40°C, the fermentation did not proceed despite the presence of remaining lactose. Although the fermentation rate had been expected to increase at higher temperatures, the result was that the fermentation stopped halfway. At 20°C, the fermentation rate was low compared to 30°C and it took 32 days to completely consume the lactose. The fermentation rates at 25°C and 30°C were comparable; however, at 25°C there was still available lactose on day 16. From these results, we identified the optimal fermentation temperature as 30°C.

Many researchers have assessed the optimal temperature in ethanol production using K. marxianus. Certainly, the thermotolerant yeast K. marxianus can produce ethanol under higher temperature conditions of about 40°C; however, the higher temperature does not necessarily yield higher production efficiency [31-33]. The optimal temperature for ethanol production may depend on individual strain and other fermentation conditions [34]. In addition, the optimal temperature for producing active superoxide dismutase was between 5°C to 30°C, and this production was significantly decreased at 40°C [35]. Although, in our investigation, we have not performed any research on genes and enzymes related to reactive oxygen species of K. marxianus in whey fermentation at selected temperatures, examinations of these genes and enzymes may reveal why the fermentation stopped under higher temperature conditions of 35°C and 40°C.

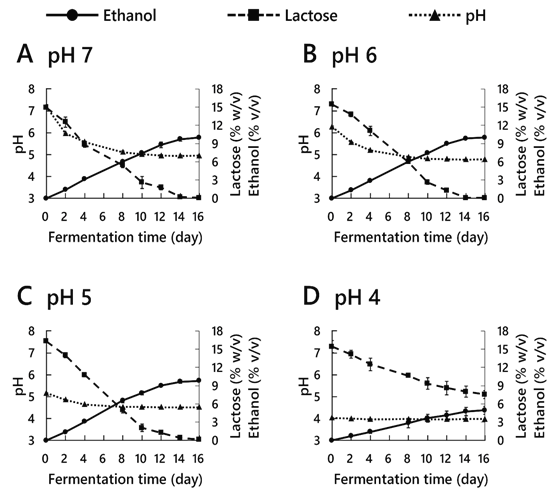

3.2 Optimal initial pH

After the selection of optimal fermentation temperature, we determined the best initial pH for DMW solutions in terms of fermentation and sensory characteristics. DMW solutions at four different initial pH values (pH 7, pH 6, pH 5, and pH 4) were fermented with K. marxianus for 16 days, followed by measurement of lactose, ethanol, and pH (Figure 2). The concentrations of ethanol on day 16 were 10.0% v/v at pH 7, 10.0% at pH 6, 9.8% at pH 5, and 4.9% at pH 4. The fermentation characteristics at pH 7, pH 6, and pH 5 showed similar behavior. At pH 4, the fermentation rate was significantly lower than that at other pH conditions. The final pH values were pH 4.94, pH 4.78, pH 4.51, and pH 3.97 from the initial values of pH 7, pH 6, pH 5, and pH 4, respectively. While no change in pH was observed at pH 4, the pH values gradually decreased over 4 to 8 days at other pH conditions.

As well as the optimal temperature, the optimal initial pH of whey fermentation in K. marxianus has been investigated in several studies [31, 36, 37]. In these studies, the optimal initial pH is pH 4.5 to pH 5.0; however, because ethanol production is lower than the present study and the initial whey concentration is different, we suggest that the pH change during fermentation is also different. Indeed, in a study by Kargi and Ozmihch [36], the initial total sugar concentration was approximately 35 g/L, and the pH decreased within the first 12 h and stabilized during the remainder of the fermentation [36]. On the other hand, in our study, the pH gradually decreased over 4 days, and we consider that the buffering capacity of whey protein was relatively high. The reason why the fermentation rate became remarkably slow under the condition of pH 4 may be that the increase in protein solubility below the isoelectric point of whey protein (pH = 4.5) had some influence on the fermentation [38]. In fact, protein precipitation was observed during fermentation at the conditions of pH 7, pH 6, and pH 5.

Since the fermentation characteristics did not change at pH 7, pH 6, and pH 5, we conducted multiple sensory evaluations to determine the optimal initial pH for sensory characteristics. In the acceptance test, 57 assessors scored the DMW-based beverages fermented at selected initial pH values: pH 7, pH 6, and pH 5 (Table 1). There were no differences in acceptance among beverages for all evaluation attributes in terms of the results of the Friedman test. We could not confirm that the amount of lactic acid added in this study made a difference in acceptability. For intensity, we observed differences for pH 7 versus pH 5 and for pH 6 versus pH 5 in the intensity of sourness, and for pH 7 versus pH 5 in the intensity of astringency. Lactic acid at a concentration of about 540 mg/L, as used to adjust the DMW solution pH to 6, should evoke a sour taste because this value was a higher level than the lactic acid organoleptic threshold of 400 mg/L [39]. However, the reason for finding no difference between pH 7 and pH 6 beverages was thought to be the influence of the taste of whey beverages and alcohol. Alternatively, differences for pH 7 versus pH 5 and for pH 6 versus pH 5 for the intensity of sourness were found because the amount of lactic acid used to adjust the DMW solution pH to 5 was relatively high. The concentration of lactic acid in the DMW solution at pH 5 was about 1450 mg/L, which was 2.7 times higher than that at pH 6. The beverages with an initial pH of 5 were shown to evoke a higher intensity of sourness than the beverages with an initial pH of 7, while the intensity of astringency decreased. A study by Beecher et al. reported that a low pH (e.g., pH 3.4) in whey-based beverages evoked a more astringent taste than a neutral pH (e.g., pH 6.8); however, the relationship between pH and astringency remains unclear at pH 4.5 to pH 5.0, as used in this study [8]. Moreover, factors other than the amount of lactic acid affect the astringency of whey protein beverages [40]. We consider that the astringency was decreased in the beverages with the initial pH of 5 due to a masking effect provided by the sourness.

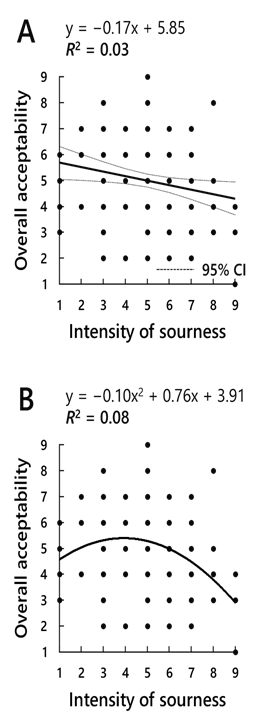

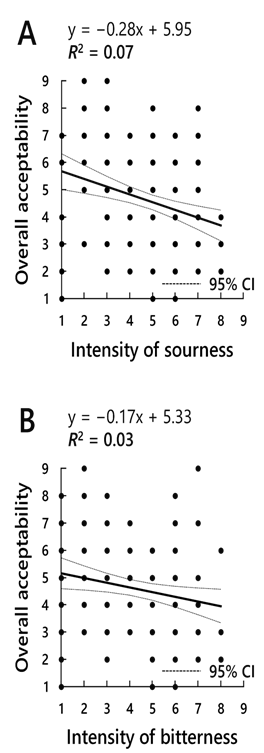

We combined the acceptance test with the descriptive test to clarify the correlation between the intensity of specific attributes and the overall acceptability using Spearman’s rank correlation coefficient. No significant correlation was observed between the intensity of astringency and overall acceptability. Astringency is considered desirable in many beverages such as red wine, tea, and coffee, and may not necessarily cause a decrease in acceptability of whey-based beverages [9]. We observed a weak but significant negative correlation (rs = 0.21, P < 0.05) between the intensity of sourness and overall acceptability (Figure 3). The result of the linear approximation (Figure 3A) suggests that the higher the perception of sourness, the lower the overall acceptability. However, the coefficient of determination for the binomial approximation (Figure 3B, R2 = 0.08) was higher than that for the linear approximation (Figure 3A, R2 = 0.03), and as can be seen from the approximate curve, the overall acceptability value was the highest when the intensity of sourness score was around 4. Although these results suggest that some perception of sourness might increase overall acceptability, there was no significant difference in the acceptance of sourness (Table 1), and the optimal pH for this characteristic could not be determined.

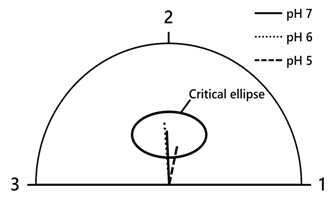

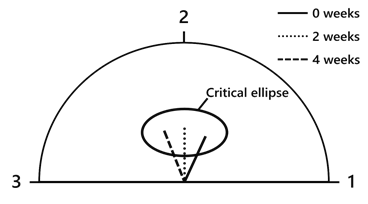

Therefore, a preference ranking test was conducted to discriminate slight differences in sensory preferences and to determine the best initial pH. The frequency of ranking given to each DMW beverage fermented at selected initial pH values is as follows: pH 7 (1st, 18; 2nd, 20; 3rd, 19), pH 6 (1st, 16; 2nd, 23; 3rd, 18), and pH 5 (1st, 23; 2nd, 14; 3rd, 20). Using these ranking data, we constructed a rank graph with a critical ellipse representing the critical region with α = 0.05 (Figure 4). The rank graphs for all beverages were within the critical ellipse, indicating that these beverages were not ranked significantly differently by assessors. In other words, because the null hypothesis could not be accepted, it was impossible to identify differences in preference regarding the variation of pH or addition of lactic acid. At pH 5, the number of people who ranked a solution in 1st or 3rd place was higher than those who ranked a solution in 2nd place; that is, there are people who like and dislike sourness in fermented alcohol beverages. Taken together, no differences were observed in both fermentation and sensory characteristics. Therefore, we concluded that it would be reasonable not to add lactic acid to the DMW solution, considering its time and cost.

3.3 Storage period

With the optimal fermentation conditions identified, we assess the effects of the storage period of DMW-based beverages on their evaluation. Three types of fermented DMW beverages stored at 4°C for 0, 2, and 4 weeks were subjected to multiple sensory evaluations. In the acceptance test, 53 assessors evaluated DMW-based beverages that had three different storage periods (Table 2). No differences among beverages were observed for all evaluation attributes of acceptance. We could not demonstrate that storage for up to 4 weeks reduced the acceptability of fermented DMW beverages. In terms of the intensity, we observed only differences in the intensity of sourness between the storage period of 0 weeks versus 2 weeks and 0 weeks versus 4 weeks, not in the intensity of bitterness. We found that the intensity of sourness significantly increased when the storage period was longer than 2 weeks. Also, the overall acceptability, although not changing significantly, gradually decreased with the length of storage.

To confirm the correlation between the intensity of sourness/bitterness and overall acceptability, we associated the acceptance test with the descriptive test. There were weak negative correlations between the perceived intensity of both sourness and bitterness and the overall acceptability (Figure 5). However, the correlation coefficient for the intensity of sourness (rs = 0.28) was higher than that of bitterness (rs = 0.19). In addition, the P-value for the intensity of sourness (P = 3.83 × 10−4) was smaller than that of bitterness (P = 1.65 × 10−2). These results suggest that, in beverage storage, sourness has a greater effect than bitterness on the decrease of overall acceptability.

We conducted a preference ranking test to directly assess the storage period. The frequency of ranking given to each DMW beverage stored for different storage periods is as follows: 0 (1st, 22; 2nd, 16; 3rd, 15), 2 (1st, 17; 2nd, 19; 3rd, 17), and 4 weeks (1st, 14; 2nd, 18; 3rd, 21). A rank graph with a critical ellipse was constructed using the ranking data (Figure 6). All rank graphs were within the critical ellipse. Therefore, we could not demonstrate that these three beverages with different storage periods were ranked significantly differently by the assessors. The rank graph with the longer storage period was plotted on the left side of the figure, showing that a higher number of people ranked it at 3rd place, suggesting that the preference for the beverages gradually decreased with the length of storage.

Altogether, these results showed that the perceived intensity of sourness increased, and the overall acceptability and preference gradually decreased as the storage period was prolonged. However, because preference did not dramatically decrease, we concluded that fermented DMW beverages could be stored for up to 4 weeks. We expect the intensity of sourness to increase over time due to the oxidation of some ingredients in DMW-based beverages during storage, but we need to clarify the reason for this by analyzing the components.

Figure 1: (A) Consumption of lactose and (B) production of ethanol during fermentation of DMW solution at selected temperatures: 20°C, 25°C, 30°C, 35°C, and 40°C. Error bars represent standard deviation (n = 3).

Figure 2: Consumption of lactose (?), production of ethanol (?), and pH (?) during fermentation of DMW solution at selected initial pH values: (A) pH 7; (B) pH 6; (C) pH 5; and (D) pH 4. Error bars represent standard deviation (n = 3).

Figure 3: (A) Correlation based on linear or (B) binomial approximations between the intensity of sourness and overall acceptability of DMW-based beverages fermented at different initial pH values: pH 7, pH 6, and pH 5. Dashed lines represent the 95% confidence interval. Results yielded rs = 0.21, P < 0.05 (cumulative total panelists = 171, Spearman’s rank correlation coefficient).

Figure 4: Rank graph of DMW-based beverages fermented at different initial pH values: pH 7 (solid line), pH 6 (dotted line), and pH 5 (dashed line). The critical ellipse represents the critical region of α = 0.05.

Figure 5: (A) Correlation between the intensity of sourness or (B) bitterness and the overall acceptability of DMW-based beverages stored at 4°C for different storage periods: 0, 2, and 4 weeks. Dashed lines represent the 95% confidence interval. Results yielded rs for sourness = 0.28, rs for bitterness = 0.19, P < 0.05 (cumulative total panelists = 159, Spearman’s rank correlation coefficient).

Figure 6: Rank graph of DMW-based beverages stored at 4°C for different storage periods: 0 (solid line), 2 (dashed line), and 4 weeks (dotted line). The critical ellipse represents the critical region of α = 0.05.

|

Evaluation attribute |

Initial pH of fermented DMW 1 beverages |

||

|

pH 7 |

pH 6 |

pH 5 |

|

|

Acceptance 2 |

|||

|

Overall acceptability |

4.95 a |

5.00 a |

5.02 a |

|

Aroma |

5.19 a |

5.33 a |

5.54 a |

|

Taste |

4.91 a |

4.82 a |

5.11 a |

|

Sourness |

5.18 a |

5.09 a |

5.05 a |

|

Astringency |

4.98 a |

4.95 a |

5.00 a |

|

Aftertaste |

5.05 a |

4.86 a |

4.96 a |

|

Intensity 3 |

|||

|

Sourness |

4.72 a |

4.65 a |

5.70 b |

|

Astringency |

5.05 a |

5.11 ab |

4.47 b |

n = 57; a,bMeans in the same row followed by different letters represent a significant difference (P < 0.05) according to the Wilcoxon signed-rank test with Bonferroni correction; 1Demineralized whey; 2Acceptance was scored using a 9-point hedonic scale: 1, dislike extremely; 5, neither like nor dislike; 9, like extremely; 3Intensity was scored using a 9-point interval scale: 1, extremely weak; 5, neutral; 9, extremely strong

Table 1: Sensory scores of acceptance and descriptive test for the determination of optimal initial pH.

|

Evaluation attribute |

Storage period of fermented DMW 1 beverages |

||

|

0 week |

2 weeks |

4 weeks |

|

|

Acceptance 2 |

|||

|

Overall acceptability |

4.83 a |

4.57 a |

4.38 a |

|

Appearance |

5.53 a |

5.70 a |

5.79 a |

|

Aroma |

4.83 a |

4.75 a |

4.83 a |

|

Taste |

4.89 a |

4.74 a |

4.26 a |

|

Sweetness |

5.19 a |

5.13 a |

4.72 a |

|

Aftertaste |

4.98 a |

4.74 a |

4.26 a |

|

Intensity 3 |

|||

|

Sourness |

4.19 a |

5.04 b |

5.21 b |

|

Bitterness |

4.08 a |

4.13 a |

4.68 a |

n = 53; a,bMeans in the same row followed by different letters represent a significant difference (P < 0.05) according to the Wilcoxon signed-rank test with Bonferroni correction; 1Demineralized whey; 2Acceptance was scored using a 9-point hedonic scale: 1, dislike extremely; 5, neither like nor dislike; 9, like extremely; 3Intensity was scored using a 9-point interval scale: 1, extremely weak; 5, neutral; 9, extremely strong

Table 2: Sensory scores of acceptance and descriptive test for the assessment of storage period.

4. Conclusion

In summary, the optimal fermentation conditions, namely, temperature and initial pH, and storage period for DMW-based beverages were identified using fermentation tests and multiple sensory evaluations. Combined with our previous research, the most preferred and reasonable conditions for producing whey-based fermented beverages were use of demineralized whey as a starting material, a substrate concentration of 20% w/v, a fermentation temperature of 30°C, and without addition of lactic acid. Other fermented beverage technologies, such as carbonation, aging, and serving temperature may increase the preference for the fermented DMW beverages, suggesting room for improvement.

Multiple sensory evaluations can assess the sample from many different perspectives, clarifying the relationship between acceptability and intensity, and increasing the grounds for judgment. Although fermentation conditions and preference were evaluated in this study, the functionality, allergy tests, and component analysis of DMW-based beverages have not been analyzed yet. Also, further research should conduct analytical testing with trained panels to assess in detail the specific attributes of DMW-based beverages.

Conflict of Interest

The authors declare that there is no conflict of interest.

References

- Geoffrey W Smithers. Whey and Whey Proteins-From ‘Gutter-to-Gold’. International Dairy Journal 18 (2008): 695-704.

- Kosikowski, Frank V. Whey Utilization and Whey Products. Journal of Dairy Science 62 (1979): 1149-1160.

- Smithers Geoffrey W. Whey-Ing up the Options - Yesterday, Today and Tomorrow. International Dairy Journal 48 (2015): 2-14.

- Clark David. Cheese whey utilization. In Eds.: Waldron K, Faulds C, Smith A. Total food-Exploiting co-products minimizing. Proceeding of workshop on Total Food, Institute of Food Research, Norwich, UA (2004): 132-143.

- Siso MIG. The Biotechnological Utilization of Cheese Whey: A Review. Bioresource Technology 57 (1996): 1-11.

- Parmjit S Panesar, John F Kennedy, Dina N Gandhi, et al. Bioutilisation of Whey for Lactic Acid Production. Food Chemistry 105 (2007): 1-14.

- Pescuma Micaela, Graciela Font de Valdez, Fernanda Mozzi. Whey-Derived Valuable Products Obtained by Microbial Fermentation. Applied Microbiology and Biotechnology 99 (2015): 6183-6196.

- Beecher JW, Drake MA, Luck PJ, et al. Factors Regulating Astringency of Whey Protein Beverages. Journal of Dairy Science 91 (2008): 2553-2560.

- Childs Jessica L, Mary Anne Drake. Consumer Perception of Astringency in Clear Acidic Whey Protein Beverages. Journal of Food Science 75 (2010): 513-521.

- Athanasiadis I, Paraskevopoulou A, Blekas G, et al. Development of a Novel Whey Beverage by Fermentation with Kefir Granules. Effect of Various Treatments. Biotechnology Progress 20 (2004): 1091-1095.

- Karina Teixeira Magalhães, Disney Ribeiro Dias, Gilberto Vinicius de Melo Pereira, et al. Chemical Composition and Sensory Analysis of Cheese Whey-Based Beverages Using Kefir Grains as Starter Culture. International Journal of Food Science and Technology 46 (2011): 871-878.

- Jacieny Janne Leite Gomes, Andreza Moraes Duarte, Ana Sancha Malveira Batista, et al. Physicochemical and Sensory Properties of Fermented Dairy Beverages Made with Goat’s Milk, Cow’s Milk and a Mixture of the Two Milks. LWT - Food Science and Technology 54 (2013): 18-24.

- Pescuma M, Hébert EM, Mozzi F, et al. Functional Fermented Whey-Based Beverage Using Lactic Acid Bacteria. International Journal of Food Microbiology 141 (2010): 73-81.

- Castro WF, Cruz AG, Bisinotto MS, et al. Development of Probiotic Dairy Beverages: Rheological Properties and Application of Mathematical Models in Sensory Evaluation. Journal of Dairy Science 96 (2013): 16-25.

- Janiaski DR, Pimentel TC, Cruz AG, et al. Strawberry-Flavored Yogurts and Whey Beverages: What Is the Sensory Profile of the Ideal Product? Journal of Dairy Science 99 (2016): 5273-5283.

- Sabokbar Nayereh, Marzieh Moosavi-Nasab, Faramarz Khodaiyan. Preparation and Characterization of an Apple Juice and Whey Based Novel Beverage Fermented Using Kefir Grains. Food Science and Biotechnology 24 (2015): 2095-2104.

- Giuliano Dragone, Solange I Mussatto, José M Oliveira, et al. Characterisation of Volatile Compounds in an Alcoholic Beverage Produced by Whey Fermentation. Food Chemistry 112 (2009): 929-935.

- Fonseca GG, Heinzle E, Wittmann C, et al. The Yeast Kluyveromyces marxians and Its Biotechnological Potential. Applied Microbiology and Biotechnology 79 (2008): 339-354.

- Melanie M Lane, John P Morrissey. Kluyveromyces marxians: A Yeast Emerging from Its Sister’s Shadow. Fungal Biology Reviews 24 (2010): 17-26.

- Guimarães PM, Teixeira JA, Domingues L. Fermentation of Lactose to Bio-Ethanol by Yeasts as Part of Integrated Solutions for the Valorisation of Cheese Whey. Biotechnology Advances 28 (2010): 375-384.

- Kosikowski Frank V, Wieslaw Wzorek. Whey Wine from Concentrates of Reconstituted Acid Whey Powder. Journal of Dairy Science 60 (1977): 1982-1986.

- Miraballes Marcelo, Natalia Hodos, Adriana Gámbaro. Application of a Pivot Profile Variant Using CATA Questions in the Development of a Whey-Based Fermented Beverage. Beverages 4 (2018): 1-10.

- Seyhan Emine, Hülya Yaman, Barbaros Özer. Production of a Whey-Based Functional Beverage Supplemented with Soy Isoflavones and Phytosterols. International Journal of Dairy Technology 69 (2016): 114-121.

- Yamahata N, Toyotake Y, Kunieda S, et al. Application of multiple sensory evaluations to produce fermented beverages made from sole whey using Kluyveromyces marxianus. International Journal of Food Science and Technology (2019): 1-7.

- Nelson Norton. A Photometric Adaptation of the Somogyi Method for the Determination of Glucose. The Journal of Biological Chemistry 153 (1944): 375-380.

- Somogyi Michael. Notes on Sugar Determination. The Journal of Biological Chemistry 195 (1952): 19-23.

- Sensory analysys-Methodology-General guidance. International Organization for Standardization, Geneva, Switzerland ISO 6658:1985 (1985).

- Lim Juyun. Hedonic Scaling: A Review of Methods and Theory. Food Quality and Preference 22 (2011): 733-747.

- Sensory analysys-Methodology-Evaluation of food products by methods using scales. International Organization for Standardization, Geneva, Switzerland ISO 4121:1987 (1987).

- Baba Yasumasa. Graphical Analysis of Rank Data. Behaviormetrika 13 (1986): 1-15.

- Mohammadreza Koushki, Mojtaba Jafari, Mohammadhosein Azizi. Comparison of Ethanol Production from Cheese Whey Permeate by Two Yeast Strains. Journal of Food Science and Technology 49 (2012): 614-619.

- Parrondo J, Garcia LA, Diaz M. Production of an Alcoholic Beverage by Fermentation of Whey Permeate with Kluyveromyces fragilis II: Aroma Composition. Journal of the Institute of Brewing 106 (2000): 377-382.

- Castillo FJ, Izaguirre ME, Michelena V, et al. Optimization of Fermentation Conditions for Ethanol Production from Whey. Biotechnology Letters 4 (1982): 567-572.

- Oda Y, Nakamura K, Shinomiya N, et al. Ethanol Fermentation of Sugar Beet Thick Juice Diluted with Crude Cheese Whey by the Flex Yeast Kluyveromyces marxians KD-15. Biomass and Bioenergy 34 (2010): 1263-1266.

- Stefano Raimondi, Elena Zanni, Alberto Amaretti, et al. Thermal Adaptability of Kluyveromyces marxians in Recombinant Protein Production. Microbial Cell Factories 12 (2013): 1-7.

- Kargi Fikret, Serpil Ozmihci. Utilization of Cheese Whey Powder (CWP) for Ethanol Fermentations: Effects of Operating Parameters. Enzyme and Microbial Technology 38 (2006): 711-718.

- Kourkoutas Y, Dimitropoulou S, Kanellakia M, et al. High-Temperature Alcoholic Fermentation of Whey Using Kluyveromyces marxians IMB3 Yeast Immobilized on Delignified Cellulosic Material. Bioresource Technology 82 (2002): 177-181.

- Pelegrine DHG, Gasparetto CA. Whey Proteins Solubility as Function of Temperature and PH. LWT - Food Science and Technology 38 (2005): 77-80.

- Engan Sigmund. Organoleptic Threshold Values of Some Organic Acids in Beer. Journal of the Institute of Brewing 80 (1974): 162-163.

- Kelly M, Vardhanabhuti B, Luck P, et al. Role of Protein Concentration and Protein-Saliva Interactions in the Astringency of Whey Proteins at Low PH. Journal of Dairy Science 93 (2010): 1900-1909.